The good ship Alchemy does not feature, as do many recreational sailing vessels of her dimensions, a multiplicity of perforations in her hull. This is due to the perspicacity of the original owner and the designer: I had nothing to do with the cleverness, except that I appreciate fewer holes in boats for reasons less obvious than "less likely to sink".

|

| Hey, two centimetres is still above the waterline, right? Dubious to me, but very common on all sorts of vessels. |

As said, she does not have a whack of thru-hulls. Below the waterline, there is one "innie" in the form of a standpipe and two "outies", the head sink drain and the galley drain. This is not the usual state of affairs on boats.

| This is from an Ericson 38: Too close together for my taste, although the rationale was probably "this is the only place one can reach". |

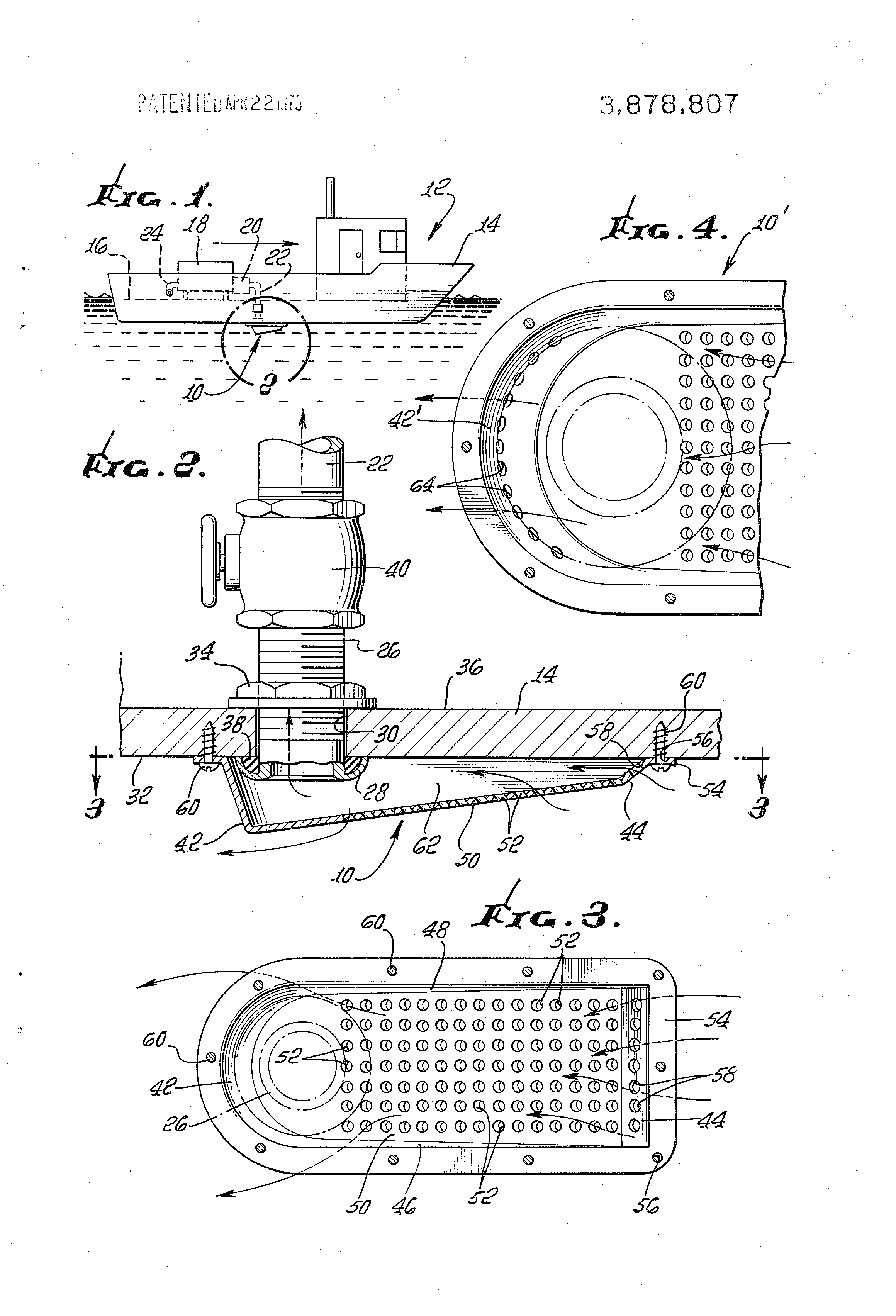

sea chest. This is a venerable sort of below the waterline grated box that allows in a controlled fashion outside (hence "sea") water to be made available for engine cooling, the flushing of heads, fire hoses, etc. The above model on a relatively small vessel is, in my experience, not the usual setup.

| Proper thruhulls screw to seacock with flanged bases, which in turn are bolted to glassed in pads. (c) crusingonstrider.us |

This is. Individual thru hull fittings screwed into seacocks, a nautical term for a bronze, brass or plastic valve, which is closed by (typically) a quarter-turn of its handle.

The usual choices made on modern yachts (and "1988" denotes a modern yacht, just not a particularly current one) is to punch a hole in the hull where needed, to insert an appropriate bronze or pretend-bronze or plastic thru-hull, and to top it with a bronze or plastic seacock, a sort of valve with a handle. This is to address the irony that while a boat is meant to float in the sea, there are many reasons to bring controlled amounts of the sea or the lake into the boat.

Such reasons include the cooling circuit of the diesel, either in the "raw" form, where sea water is sucked through the engine by means of an engine-driven impeller, or in the confusingly named "freshwater cooling", where the seawater is used in something called a heat exchanger (a sort of radiator) to transfer the engine's excess heat from a closed and pressurized circulation of antifreeze to the sucked-from-outside seawater, which is then propelled out of the boat with the pressurized exhaust gases. It's a generally robust system, even if the glycol mix in the sealed engine circuit isn't really "freshwater" at all. The point of the glycol is twofold: Firstly, antifreeze, "Dex" or glycol is more effective at absorbing and yielding up the waste heat of the engine than is straight water. Secondly, it is less corrosive than fresh water (in terms of engine metals) and quite a bit less corrosive than seawater, which yields its salts and other crud-making substances at the relatively low temperature of 155F or so. If a diesel has to work inside a watery jacket, it manifestly prefers that jacket to be under boiling temperature, but not much...175F to 190F is typical.

|

| S/V Alchemy's easily accessed standpipe withT-fittings for head, engine and A/C, plus a spare for saltwater supply to the galley. Also seen are the fuel tank manifold/valves to the right. |

You may consider the following depending on the layout of your boat: a standpipe. Above is the one on Alchemy. It's essentially a vertical seachest, with the important distinction that the top of it is customarily well enough above the waterline of the boat to permit service and cleaning...without hauling the whole hull out of the water, or, conversely, going to a place with impressive tidal ranges.

|

| Super-duper standpipe (c) setsail.com/Steve Dashew. This shows the strainer elements close to the pipe, plus a similar "cap" as to Alchemy's. |

A standpipe is a straight metal pipe either welded directly to the hulll or screwed onto a thru-hull base. It can be secured by bracing if needed. As noted, it extends above the waterline and is capped with a gasketed (again, usually metal) cap. It resembles the old style oil fill tubes on the sides of North American houses from when oil was a common furnace fuel.

Down the pipe, below the waterline, are welded-on T-fittings threaded to take sea cocks. Put in as many as are required and can safety fit in regards to access.

|

| The standard approach, but who wants to dive under the boat to remove a couple of screws? |

The advantages are many in that you have only one "intake" hole in the boat. Fitted with a hinged screen or filter, you can, should you suck in fish and/or debris, open the top cap, see what's down there, and use a length of dowelling or a small-calibre weapon to clear the entire standpipe.

|

| Getting there, but you still have to dive on the boat. Why not a heavy spring on that little door? It's a plot by skin divers. |

There is no particular reason that the seawater intake must be forward of the engine, other than that forward is usually deeper in the water and less likely to be above the waterline or in agitated, bubble-filled water if the boat is heeled sufficiently. Getting "gulps" of air in the raw-water intake circuit could indeed lead to problems, so you have to figure out the angles. Generally, making the lowermost T-fitting on a well-placed standpipe the engine cooling feed would do the trick.

As for positioning, you can "hide" in under saloon stairs or inside a piece of galley cabinetry, just as long as you can reach all those seacocks/shut-off valves and can look down the standpipe to both see blockages and deal with them.

The standpipe in my steel motorsailer saved my engine when I noticed the engine temperature rising despite the proper functioning of the engine pump. I shut down the motor, looked down the standpipe and saw that we had sucked in a large, thin plastic bag obligingly occluding the raw water intake. I was able to push it down and out with a stick designated for this purpose, and we resumed motoring with no further incident.

| Typical, but no good for steel without some way to keep the metals apart. |

Some methods of stopping this sort of thing happening are above; most sailboats have a simple brass strainer of the type pictured. Others have rather more massive perforated grates for sea chests.

|

| Arr, that'll keep ye out, Squiddy. (C) www.sbmar.com |

Many folk are aware that a bag or a particularly gnarly weed or even small creature will get munched in the engine's water pump, which contains a fast-moving impeller capable of Cuisinart-like execution. To keep macerated "bits" out of the surprisingly delicate engine cooling passages, however, a further measure is needed:

|

| Increasingly common on boats "pre-engine" and "post-impeller", this basket filter can save your engine if you suck in a bag or a significant amount of sealife or vegetation. (C) Colin Speedie |

A relatively common sight on boats is the bronze raw water strainer. Here's Groco's factory-fresh version:

| The Groco model. Aside from plastic versions made by Vetus et al that resemble coffee basket filters, Perko and Groco seem to have the market cornered. |

|

| This was opaque with greenish residue before a hearty soap-n-swill. |

|

| The filter works as advertised. Even in Lake Ontario, sea muck abounds. |

I gave a light scour to the brass parts. It doesn't have to look like a Viking's tankard.

|

| Don't expect that hatch floor to get cleaned. It's headed for the bin. |

| |

| I'll leave the Brasso rub for another time. |

The fly in the ointment of all this wonderful diesel-aiding cooling process and planning and design is, like the fly itself, an invertebrate. And, without being overly dramatic, it may pose a greater threat to cruising than world economic collapse, rampant yacht piracy or even nautical zombies.

|

| This is what's left when you gobble the top three tiers of the ocean environment. |

Most of us, outside of certain Pacific island nations and Australia, where most of the wildlife seems bent on killing the inhabitants, likely do not consider the humble jelly, a varied and diffuse collection of species that have been doing their glutinous thing since the Cambrian era, a significant threat to human safety, or, Neptune forbid, the cruising lifestyle. Most of us would be mistaken.

|

| No matter how downtown you think you are, do not place on genitals. |

|

| We're gonna need a bigger filter. |

And who's to say our time-honoured traditions of eating our problems won't help here? But you can't catch everything, and as a person who wishes to dive coral reefs in the Pacific, I have to wonder about what's not eating this little fellow, and did he bring his friends? And, having turned the oceans into nutrient-free lubricant, will they find a way to leave Earth?

| One wonders what the standpipes on Enterprise are like? Nice bits of kit, one hopes. |

|

| The future of "it's what's for dinner". |

Oh, and we need to eat these buggers, too. And these excitable bastards. Along with rapacious fishing practices and a general curtailment of human population, of course. I like to think I'm fair.

But not when it comes to the cooling circuit? No compromises.

11 comments:

Marc, not sure about the segue from strainers to jellies but good post anyway. ;-)

Before heading out from Toronto back in 2008 for saltwater cruising we removed every last outside through hull inlet strainer on the hull, all four of them, head, galley and deckwash. Glad we did.

Miniature critter larvae love to colonize thru hull mechanisms. They will drift/swim through those holes in the hull mounted external intake strainer, grab on to a likely place and then proceed to eat and...GROW. Barnacles not so much, but coral polyps, mussels and oysters and other shellfish will do this. That external strainer mesh...especially the lovely stainless one in the Groco with the cute little cleanout door, will be plugged with the rock hard, ceramic like calcium deposits forming the shells of these guys. We swim around the hull almost daily with an old screwdriver with a floating handle. A little thrust up each open thru-hull and a twist of the wrist evicts the buggers.

I do like the post seawater impeller strainer thing...it'll collect the rubber vanes as they're shed by the impeller, rather than finding them in the heat exchanger inlet. We have a seawater flow alarm sensor (still in the box) that should warn us of a seawater engine cooling clog. By the way, we discovered that the seawater calcium scale alst builds up in the seawater loop, hoses and strainer elbows. Just looking into the engine strainer bowl wasn't enough...we didn't see that the bronze strainer inlets were scaled up...kinda like a 50 year old iron water pipe in Toronto.

Thanks, Ken, what can I say...I like to mix it up. It was the increasingly common problem of swarms of jellies screwing up water intakes at power plants that got me thinking about strainers and so on.

So I guess you are suggesting that if I have a standpipe that is open to the sea, that I just avoid any kind of a screen because it will only clog over with critters? That would suggest I keep filters on the inside, which was Plan B.

The basket filter thing is cheap insurance. I've yet to catch an impeller vane in it, but I have kept little shreds of plastic and some equally torn up animals and plants out of the block.

The seawater flow alarm is great; a similar device measures temperature of the water before the exhaust mix and, through an alarm, lets you know if you are exceeding 200F. When you install it, I would love to hear your opinions on it.

I'm aware that very regular critter removal is the cost of being at anchor. Have you considered fresh water flushing (or backflushing) of selected hoses? It might argue for a watermaker after all. We have loads of room for water tanks, but I was considering the utility of a smallish watermaker for drier parts of the world, and for the ability to divert tank fresh water from a dedicated tank into the head and galley for flushing purposes.

Hauling out Alchemy on Saturday. I expect to motor away at launch as all the pieces are aboard. Thanks for writing.

Hi Marc. Here is our seawater flow alarm. http://www.sailorssolutions.com/?page=ProductDetails&Item=FS200

We made the decision to find out about lack of seawater flow rather then wait until the engine overheats due to the blockage. Trouble with hi temp alarms, it could be a blockage or lack of coolant in the freshwater loop as well as seawater. The flow alarm just measures flow and yells at you when the lower limit is sensed.

Freshwater flushing of seawater hoses isn't desirable or even possible on Silverheels III as we catch water on deck, buy it sparingly from marinas and do not have any electric pressure for fresh water. We've pumped by foot for ten years now and we know how to save water....a good skill to develop in preparation for those dryer areas you allude to. ;-)

Our friends and yours too, Paul and Sheryl on Distant Shores II elected to leave out the watermaker on their latest boat. They have the water tank capacity to travel across the oceans and hated the expense and hassle of watermaker purchase, maintenance and spare parts inventory to make it all go.

Lynn and I can buy a lot of water for $5k+ and we like the "cruiser's gym" (hefting the jerry cans.)

It's still up in the air, Ken. We have room to carry about 200 gallons in the engine room, but in some ways I'd prefer to carry half that and use solar and wind to make as needed. We, too, are foot pedallers, but the difference is that with a full keel, water tanks are an element of internal ballast. We need more than some do, and what most can have in a fin keeler is less than we would want, including rainwater for washing and flushing, not just drinking.

We'll see. It's not a today thing. The today thing was Becky down at haulout in a rain-swept gale discovering that the sling marks were a foot wrong due to the addition of the engine. I understand (I was off making money) it was an exciting moment.

If I can find Paul or Sheryl I will write them to better understand their logic. I wasn't thinking particularly elaborate rig, but I remain open to contrary views.

DS II is four slips away in our Grenada marina.;-)

Huh...I thought you were on the hook! Congratulations on your lottery win!

No lotteries for us.....first time on a dock for general repairs and maintenance (dinghy too) in 5 years. Can't repair a seawater leak on a dinghy when you're at anchor.

Great post, and educational.

Now I know why my engine runs cooler (too cool) after replacing the 10% antifreeze with a 50% solution. I read that it shouldn't make a difference, but it does.

I have ONE underwater throughull and a sea chest. The galley water flows out a hole just above the waterline - the sinks gurgle like hell when heeled.

What about the head, you may ask. It goes into a holding tank which is manually pumped out also just above the water line. For obvious reasons, I pump it out when it's dark.

Oh yes, a throughull with an exterior grate, holes...whatever...is for the barnacles and a damn nuisance.

I assume you mean the "freshwater" circuit (a stupid name as it's usually a glycol/water mix and is hardly fresh) that is too cool.

I think you need to independently check that your engine coolant is in fact cool and that your temperature gauge is not faulty.

As for the barnacles, the percebes kind are delicious!

Anything is possible.

This is how it went: motored to Nazare to haulout with the gauge showing about 180ºF at the usual revs (just like always since I left Canada 11 years ago).

On the hard, changed from cheap 10% antifreeze to a quality brand 50% antifreeze.

Ever since, been to the Algarve and back and temperature always stays at about 155º unless I gun it past my cruising speed.

My car mechanic said the same as you (but in Portuguese), "no way pá [man], gauge is faulty, maybe thermostat is no good...."

Big coincidence, I'd say, pá.

Ryker says that maybe by draining the antifreeze I cleared up some foreign bodies that were hampering the flow...that would still leave me with a faulty gauge - it's supposed to run at 180ºF. Oh pá, the life of a boat slave!

Horatio, I can't tell you anything you don't already know, or suspect. You may have flushed your system better than you know.

I will suggest something, however: You need to figure out if your thermostat is in the raw-water (seawater) circuit or the coolant (antifreeze, pressurized around the engine and circulating through the heat exchanger, which my Portuguese sailing buddy calls a "calorifier".

The reason is that 155F is as hot as you want the raw water to ever get, because the salts in seawater precipitate out at that temperature and can leave deposits in your exhaust system...although realistically the hot exhaust gases are going to heat up the water a lot, too.

You should observe if the cap on your heat exchanger is the right pressure rating, and what is happening to your expansion tank when at cruising RPM...is the tank filling? Is the level changing?

That's where I would start, although as long as you don't have a leak in the block itself (you would see coolant in the oil...bad), I'm not sure you really have a problem.

I saw some surfing videos from Nazare. It looks a little difficult for a sailboat with the 30 metre waves!

Post a Comment