|

| How hard can two rectangles be? I guess we will find out. |

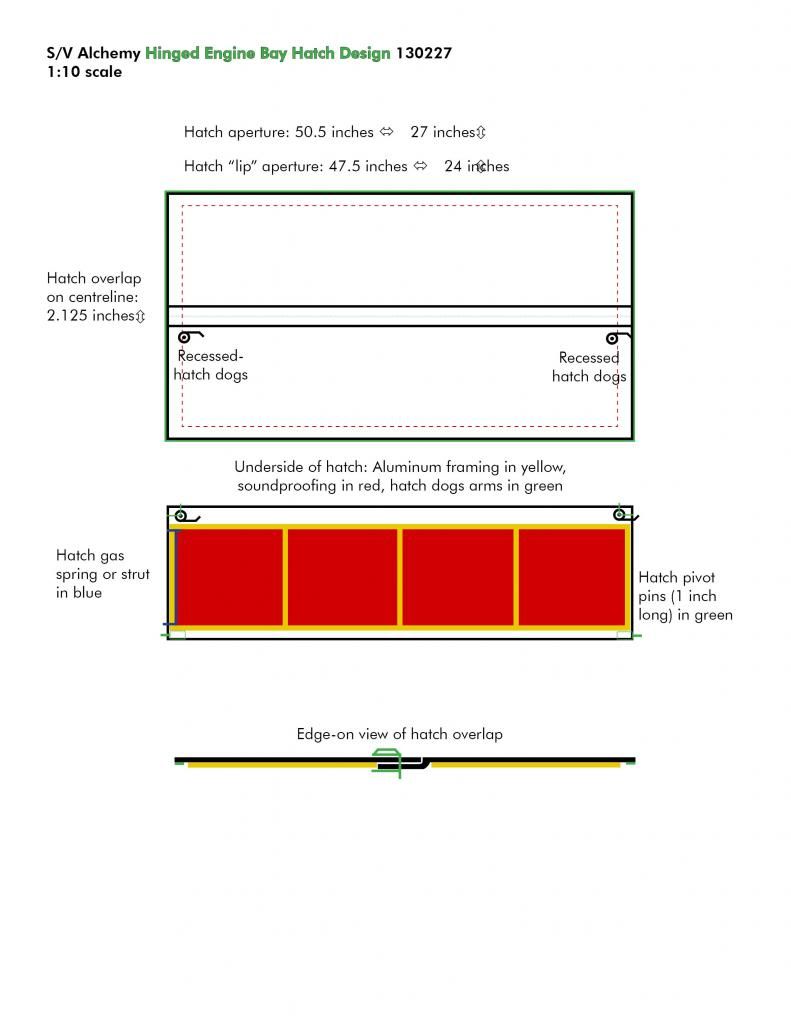

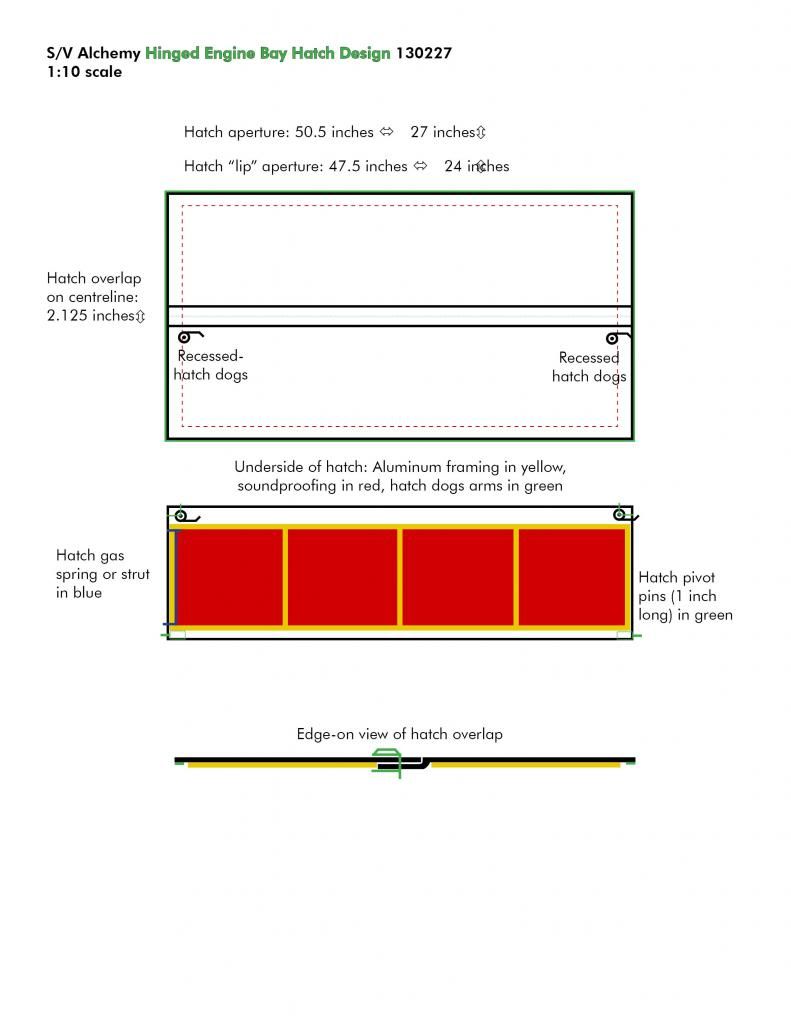

Recently, I've had to research every type of "

gas spring", which is the name of the category, by the way, for the lifting mechanism of every sort of hatch or platform that is heavier than something a simple bronze or stainless strut would hold open with confidence, which is why it's top of mind.

|

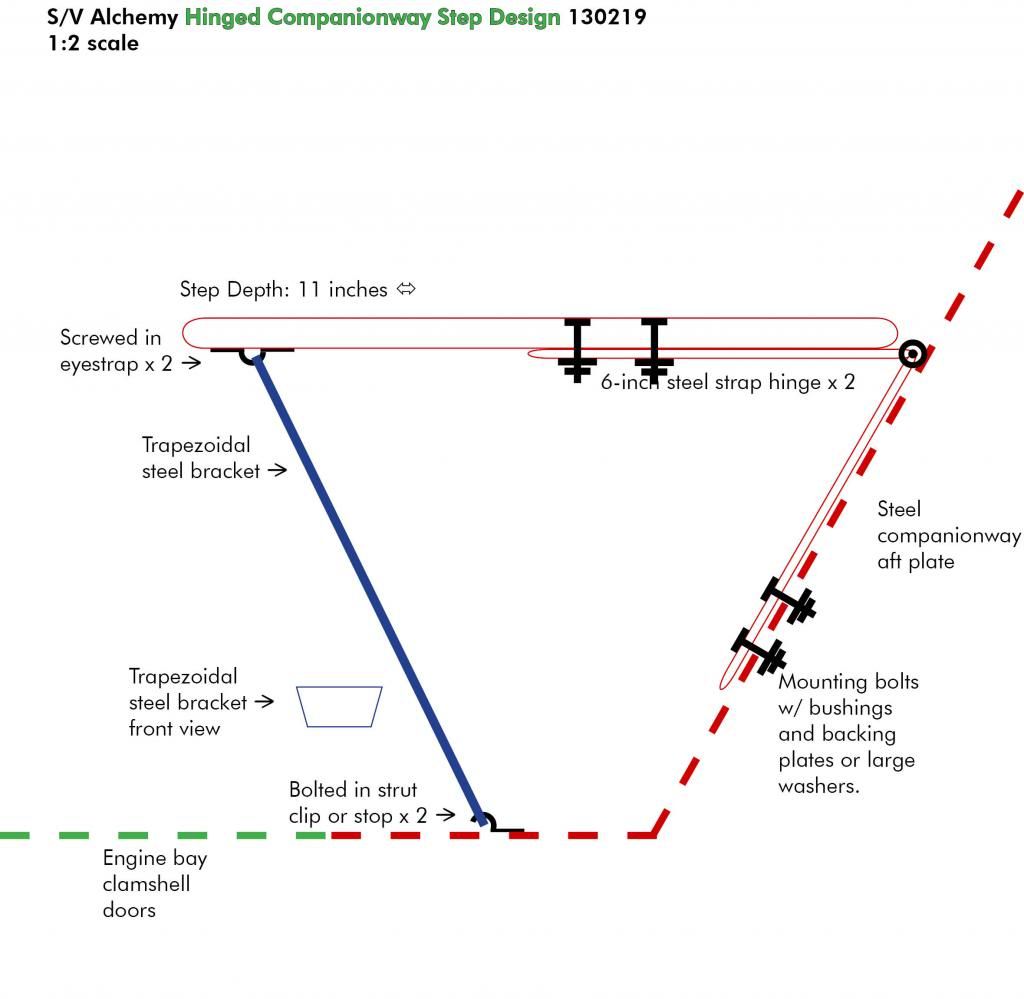

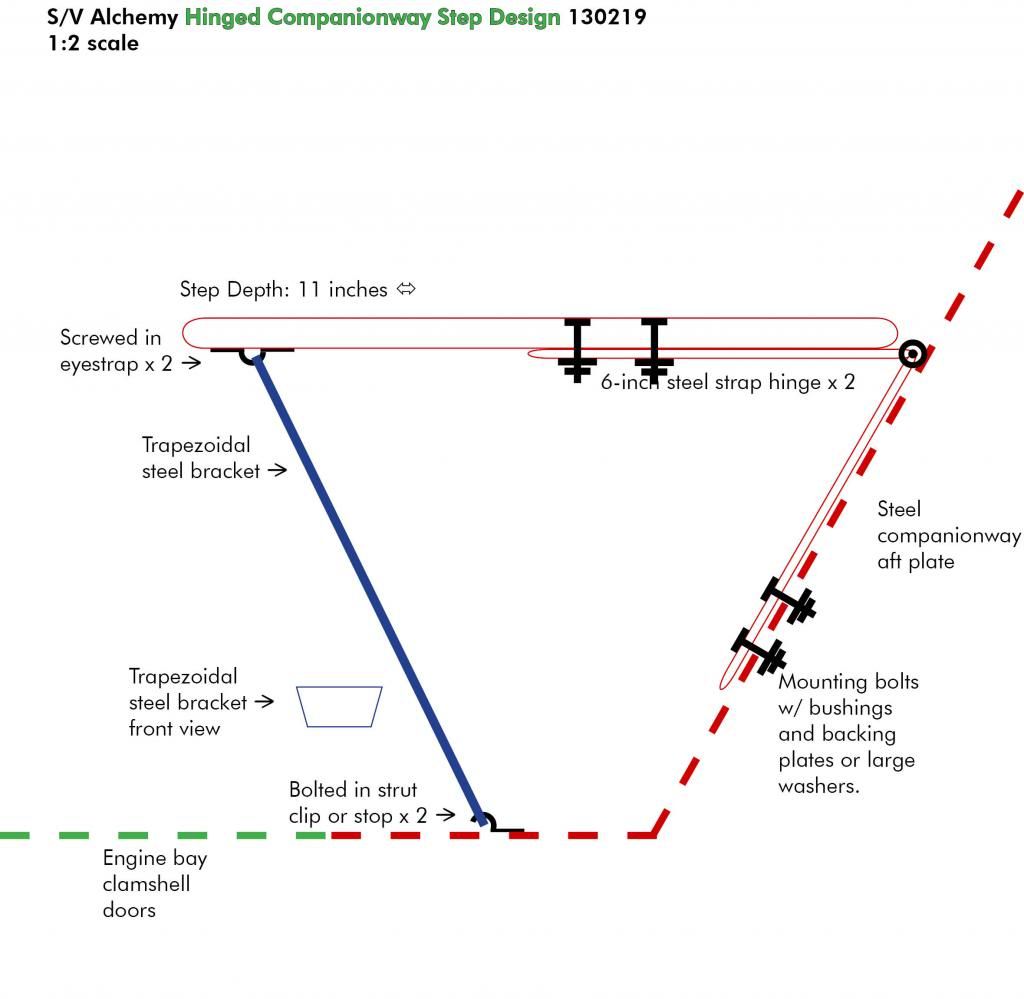

| Related project to the engine bay "clamshell" hatches: For them to open, the last step into the pilothouse must raise or lower out of the way. |

The ongoing engine stringer/thrust bearing project (more on this soon) was made easier by the removal of the lowest step of three going from the aft deck down into the pilothouse.

|

| Watch that last, missing step. It's a doozy. |

Removing this gives enough "air" to get a welder down and around that engine, which needs to be flown up and secured once the welder is down with all needed gear. It also would be latched in the up position when the bay hatches are upright. After a bunch of fruitless searching for a folding bracket that would fold up, and not down, and yet could support a human's weight in a seaway, all I could find was

something representing overkill in several respects:

|

| Works in the right direction, but is too big and too strong. |

So my design is much simpler. An eye and hook can secure it, or even a loop of bungee, and a metal "C-strut" can support even the impact weight of a wet crew stomping on it.

|

| Pretty representative of the genre |

As for the bay hatches, this type of gas spring is nice, although I could just as easily use the very same sort of sliding hatch strut used on most deck hatches. The doors have to be kept open, and that means only their own weight has to be supported when open. When closed, the frame of the "bay hole" itself, plus the overlapping center "lip" does that job, unless my design, currently under review by a fabricator, is insufficient.

On the subject of where the backsides go, as the pedestal type of gas spring for helm seats are

quite spendy, you could get everything from a bus driver's seat mount to a salvaged barbershop chair base to accomplish the same action in a compact manner.

|

| Priced with the customary "Marine means times three" factor |

We actually tried to acquire a "salon chair" for $99 last year, but we didn't get a call back. Might have been a dodged bullet, as I suspect the pedestal to seat plates and pedestal to floor connections are both robust and less prone to corrosion than barbershop specs typically are.

The reasons for this particular line of enquiry is because there is a height discrepancy between my wife (and my son for the near term) and myself. We therefore require a helm seat in the pilothouse that can move up and down and fore and aft. Ideally, a sailing helm seat would pivot side to side on some sort of friction fitting, either to make sailing on a heel comfortable (if one was, for instance, on a night watch during a cold rain from the pilothouse in the mid-Atlantic) or to shift side to side in a cross-swell. According to a recent thread I started in Cruisers' Forum, however, that particular sort of pedestal seat base

doesn't seem to exist currently. So it may end up being another fabrication job, or we make do with an off-the-shelf solution.

|

| Eh, may be overkill...the measuring tape will confirm, but the arm and foot rests are nice |

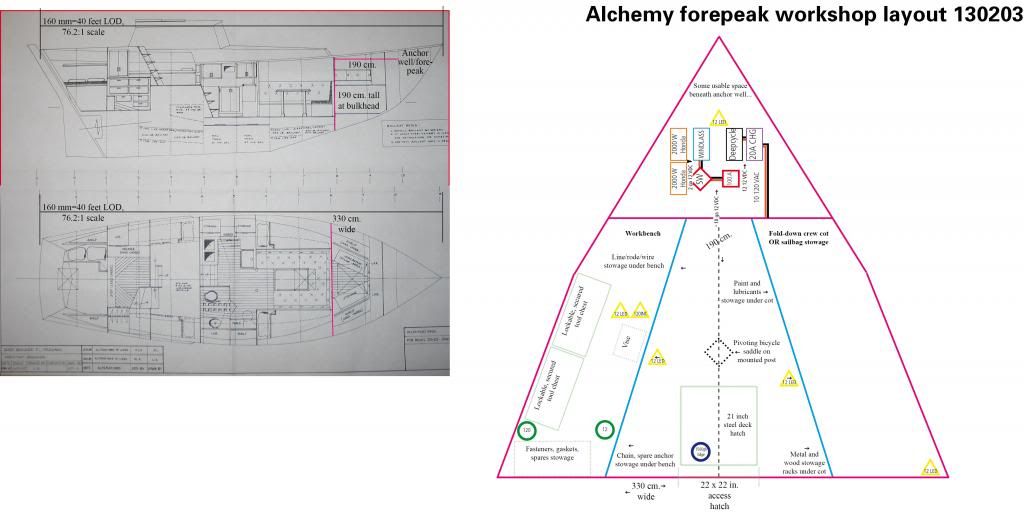

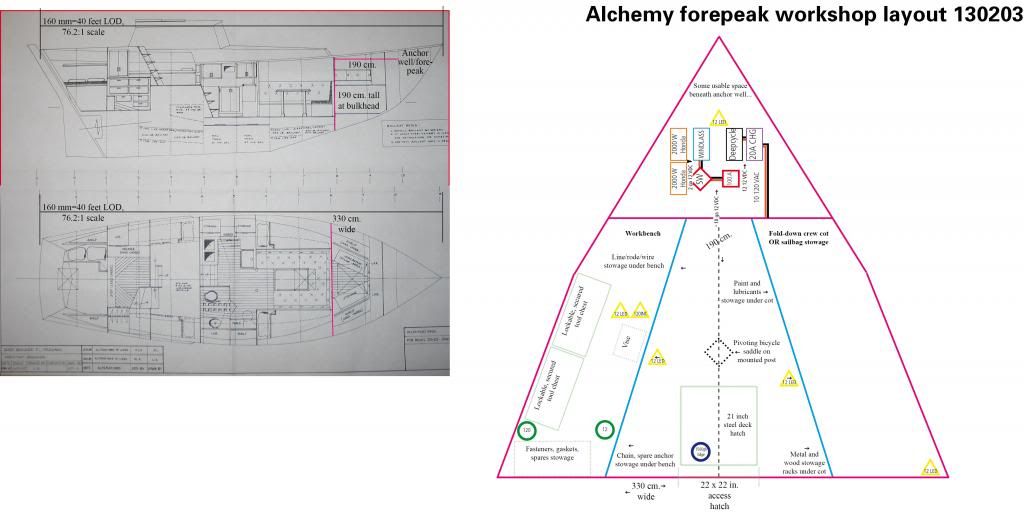

Strangely, I have done exactly that with the seating solution I envision for the forward workshop. Preliminary designs, taking into account the time likely to be spent in there, the need to shift my weight and the space available, gave me a very quick idea I might not have otherwise had if I drove a car: a bicycle seat on a post. For better or for worse, I am used to bike saddles, and I can literally salvage everything I need out of my garage. I can even make it spin...

|

| I'm looking forward to this part of the rehab, actually. It's probably within my skill set to do it right. |

Back to the "strutting", I need to investigate gas springs for my engine bay hatch and my steel forepeak deck hatch, both of which will be "unlight". Another dinette-weight project will be the new saloon companionway steps I am planning to frame up, which will cover eight Trojan L16s in a welded, stepped box, which will themselves contain battery boxes for each pair. One of the very few things I like about

current showroom queens are the gas springs that allow a companionway hinged at the top to rise with a kid's grade of arm strength and stay put under pulled down, much like a well-fitted sash window.

|

| This is bigger than I'll need...it's from a Beneteau 55... but picture something similar going up like a van's rear hatch. |

The point is to take all the half-ton of batteries I intend to carry right to the CE of the entire boat, meaning I can dispose of the lead pigs acting as trim ballast forward...and replace it in part with tools and spares.

The

gas springs used for truck engine hoods should be about the right size. You could use gas springs in combination with a locking strut in a number of applications around the boat in a similar fashion, including fold-away or fold-up table or nav station surfaces.

Lastly, today's hot boater tip is that

Lee Valley seems to be selling

moddable warm white and coloured LED strips for a price I find reasonable, and will do so for bulk discount. Many sailors have for many years been taking out the old auto-type 12VDC incadescent bulbs in favour of LEDs, particularly as the first-generation "cold and bluish" type have declined in favour of "warm white. But this Lee Valley system is more or less snap-together, looks nice (I've seen them in person) and dimmable, all attributes that are like catnip to the amp-conserving average boat fixer. I saw the RGB ones and thought "hey, go from 'blended' white to pure red in the pilothouse with the turn of a pot dial? I can get behind that!"

|

| Part Lite-Brite, part Lego. |

Naturally, I think LEDs are the absolute bomb in any boat place that requires small amounts of light (like inside lockers soldered to a 9V battery and a contact/reed switch), or for "mood lighting" under the lips of cabinets aimed up or down.

We are pretty much at the break point between me wiring up strips off a spool obtained from an "industrial concern" and the price of retail at places like Lee Valley. I thought I'd have to make and measure my lighting, but it's going "prêt-à-porter": just buy what you need and screw it down.

One could easily neglect to check certain dials, digital displays or indicator lights on the modern boat, and thus fail to note (or have the watchkeeper fail to note) engine overheating, low oil pressure, water ingress or some other potentially fatal condition, like a propane leak or CO build-up, requiring immediate skipperly attention.

Having had low oil pressure and cooling water overheating issues on our boats in the past, I am a fan of early warnings. There's a gas/propane sniffer on Valiente, along with a CO detector. I typically check for "output" of cooling water at the stern and eyeball the temperature and oil pressure dials of the very basic Atomic 4 control panel, and so haven't bothered with buzzers. On Alchemy, I will install more alarm setups because more of the critical systems could self-destruct without immediately noticing the process, and also because, frankly, there is a lot more at stake than aboard a Lake Ontario day sailer.

Plenty of alarm widgets or alarm systems exist for the cautious/paranoid/typical cruiser, and some are very clever indeed, and cross over into the solenoid or automatic actuator realms.

But I wonder: why don't boat system alarms talk? Cars talk, GPSes talk, even cheap alarm clocks murmur instead of buzz. Even smoke detectors can shout at one. Even personalized smoke detectors exist.

Voice recognition, as fans of "Siri" know, is a thing of the present. So why should a host of boat alarms buzz with essentially the same range of tones?

It should not be massively difficult to replace that growing host of various buzzers with the sort of circuitry that is found in “talking/singing birthday cards”, or “talking seatbelt alarms” in cars and the like. Or to rig just the chips capable of holding a two or three word message, along with a small amplifier, to make a personalized alarm.

Imagine hearing instead of some random buzzer in D sharp, you heard your own voice saying “Fuel pump overpressure!” or “Bilge past six inches!” or the very useful “Exhaust temperature past 100C!”

If one did not wish to actually record specific messages, one could simply throw in random…but distinct…noises on pre-recorded chips, like "birdsong means bilges", or "fly buzzing means fuel", and so on.

It’s the distinctiveness of the alarm noise that is desirable. Buzzers tend to sound alike, because they all come from the same factory in China, I would imagine. Voices...now, the human mind zeroes in on those in terms of direction and content far more easily. Of course, if you find the idea of a verbal alarm a little creepy, there are some less buzzy options.

Picture combining the “talking alarm” with “The Clapper” for a shut-off, and you’ve got the basis for a marine products empire where the average customer’s age is already well past “I should’ve worn earplugs during that Alice Cooper tour in '72”.

Personally, I am not quite that age, myself, and due to plenty of deafness in my family, I have both nursed my hearing and had it regularly tested; it appears I'm in good nick. Spend time at an average boat club, however, and it's clear a large percentage of Boomers have listened to a few too many booms to hear their pants ringing in anything but a dead-quiet environment...which the sea is rarely.

Like my idea for dim, five-second red LEDs that would be triggered by movement across the sill of companionways at night, or a 9V battery-powered, reed switch-activated, under-lid LED locker light, I do not see a strong objection in cost or complexity of a “talking alarm” to easily distinguish what part of the boat’s systems is complaining.

It only sounds like Star Trek. The actual electronics involved would not be beyond the average electronics hobbyist, which most cruisers already are, because they can't afford not to be. I built kit shortwave radios and repaired my guitar amps as a teen and still do various electrical bench work (I'm trying to reboot an old Furuno radar I found, for instance); I don't think any of this at the level of "home-brewed" is very difficult to rig. If someone's already invented these sort of gadgets, I would enjoy hearing about it. Just not in the form of a buzzer.