|

| Clearly, I may have overthought this. |

Winter and hurry up and wait freelance employment give the earthbound sailor time to mull and to ponder various infinities, and many sailors do have philosophical bents. A sailor's boat, however, is a finite space: no matter how large or small, most skippers would prefer more space in which to put more things. The list of tools and spares is long: there's never enough money or space to carry every damn needful thing. So it's important to plan not only

which spares, consumables and tools are brought along, but

where they may best be kept and

how.

|

| Bloody luxury |

The thing is, boats

move. I know, I know, this is not readily apparent if one walks the docks of many a Great Lakes yacht club, but it's true. Not to tell anyone how to use their boats, but fair-weather sailors can pack a plastic tool box in the lazarette. This sort of post is not for you.

|

| These are simply rust-deterring versions of the sort of mats many aboard use to keep their dishes from moving around the saloon table. |

For those for whom tools are essential ballast, movement, particularly of tool metal on tool box metal, is

undesirable.

|

| This product is used in gun cabinets, but I see no reason it wouldn't work in tool boxes or drawers on boats. |

So is the resulting possibility of rust.

Mitigating rust is a priority, given that stainless steel tools are very expensive and yet, in certain cases, are

not as good as the usual alloys.

Tools, the extensive ones I wish to bring because of delusions of competency and a desire for self-sufficiency, do not move if you stow them in foam insert in lockable drawers in chests throughbolted the steel collision bulkhead, but still, there are considerations. In the photo above, I do not see fiddles nor enough of an overhang to apply clamps, two things I would miss at even a modest heel.

|

| This is more like it: the workshop on a steel Brewer 50 for sale here. |

Note how some onboard workshops incorporate clever ideas. The usual sliding door cabinets are pretty standard, but in the photo above, open shelving is angled downward at the rear so that loose objects within, including awkwardly shaped things like what appears to be an assembled Henderson pump, can stay put but accessible unless the boat's heeled so far over that the crew have other pressing concerns than crashing noises coming from forward.

|

| A characteristically Spartan workspace, but not wildly different from what I want, save for the headspace. |

Sailing veterans Larry and Lin Pardey were, over the last few decade, about the ultimate in self-sufficiency. Having met them, I can say they are also compact enough that I suspect the modest if incredibly tough boats they lived aboard did not present an issue, but

Larry's ingenuity allowed his tools to be stowed both safely and without corrosion.

|

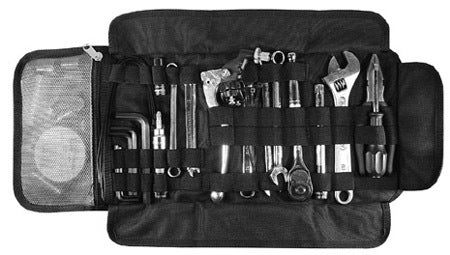

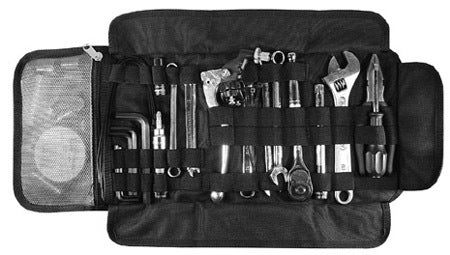

| Caddy-type bags and tool racks are best considered temporary storage. A screwdriver would fret through that quickly at sea. |

|

| Another solution, or perhaps an additional one, would be compact but tough tool bags. With attachment points, naturally. |

|

| I've seen this and various "pegboards" on boats, but they don't inspire confidence as a tool chest does. |

|

| Fine for a four-sided garage, but for a forepeak? Not so much. |

You

do have the typical tool caddy or plastic rank thingies on some boats (see above), but that's just

to keep them handy while working. When the job is done, the workbench

must be

completely clear unless you are clamping something; then the

clamps themselves must be lashed down. Because...boats move.

|

| The workbench on Morgan's Cloud: If you want a good tool space to emulate, this is a great picture to mull over. |

Above is the workbench area of

Morgan's Cloud, a

McCurdy and Rhodes 56 foot cutter in aluminum. John and Phyllis Harries, her owners, are fans of high-latitude passagemaking: access to tools and spares is critical aboard a boat that at any given point might be a thousand miles from the nearest SAR facilities, never mind a well-stocked chandlery.

Things I find of note in the picture are the aforementioned heavy fiddle. Not only should this catch most tools and fasteners should the boat give a lurch, it's also a handhold for the person doing the work. Note also the mounted plastic fastener organizers and the toolboxes lashed into place by webbing for storage AND held with eyes screwed into the bench top. That vise is nice, too, and right-sized for repairs...I think at least one of the skippers is left-handed. Jammed into the corner, there is a "ditty bag" of assorted tools suitable for a grab-and-go job and for taking up the mast securely from a lanyard from the bosun's chair. Lastly, there is what appears to be a snap-down cover to keep ongoing projects from taking flight. A nice bench in a tight space that appears to have seen a lot of action.

|

| I think this sort of thing exceeds my skill set, but it's a beautiful piece of kit. (c) Sailing MeVoy |

Some sailors, of course, bring woodworking skills to bear. This toolbox above is indeed beautiful and wonderfully well-made, but it's "too beautiful" for me. I prefer metal or plastic boxes for tools, because if I can't keep them coated in

CRC or

Boeshield or some similar rust-inhibitor, they won't last long or work properly at sea. This implies the possibility of tools staining or marking the trays in which they live, and that would damage a wood tool box.

|

| This is better than the foam inserts because of the better use of space and because you usually want more than one wrench. |

This sort of organization appeals to me as a good way to store tools in "ranges", as this is more or less the way I sort them currently.

|

| We've got a bigger boat. We're going to need a bigger bag. |

Of course, you don't need the traditional tool boxes with loose tools, which could get damaged moving about unless they are packed pretty snugly or with dividers or inserts that won't absorb the salty air. Reader and sailing buddy Jeff Cooper points out that "tool rolls" were once the standard on the old cars he restores and are still a good idea. Compartimentalized bags "open up flat for easy use, [are] well organized and roll up for security and take up less space when stored." An advantage here, I think, is that a sturdy box with a front-mounted lid and a very secure hinge and hasp/staple could hold several of these roll-up tool selections, labelled and perhaps even colour coded for ease of access. The heavy rolls, packed properly, aren't likely to roll and therefore chafe, but the choice of material would, again, have to be non-absorbant of sea air.

|

| These roll-up bags can get quite elaborate. |

|

A "low-buck" choice for stowage of such roll-ups, which a reasonably skilled person could sew up from fabric scraps, as has

Low-buck Yacht Club member Eric Van Andel here...

|

| Photo (c) Eric Van Andel |

|

| Nice work, there. Photo (c) Eric Van Andel |

|

| Like a spring roll in your tool chest. Photo (c) Eric Van Andel |

...would be the seven-kilo square kitty litter bins which are very popular on boats, even cat-free boats. Lashed shut and lashed to the boat, they could keep the tools in place and yet keep them from chafing. And they are free for the repurposing.

|

| I'm never this bored, but it does show the versatility of these plastic bins. |

|

| If they are durable enough for winter biking, they will probably survive your under-settee stowage space. |

The idea of a bike seat in the workshop is a pretty obvious one, I think: it's cheap, it pivots, it is easy to mount to the sole and it keeps my legs well-braced. Best of all, I can move it and stow it if I need to stand or to maneuver inside this space.

Decent lighting in a workshop is important: While I have a 21 inch square steel hatch I can fling open, I would be cautious about doing so in anything but a benign sea. This hatch, which needs a different method of sealing I will discuss in a future post, has a 5 x 12 inch opening port for some light and ventilation, but there are both 12 VDC and 120 VAC runs from the electrical panels to provide "ship's power" lights and enough power to a conventional AC power bar from shore or inverter to run strong lights, and items such as a small vacuum, drills or grinders. The least obvious item in the drawing at the start of this entry is "

the chain trug"...more on this later in the year when the windlass is installed! The hatch into the salon is still a "perhaps", but I would love in bad conditions not to have to climb onto deck from this workshop to get back below. Another advantage would be in communicating with the rest of the crew while forward, and to pass items (boom ends? whisker poles?) into the workshop So that's still a question mark, as discussing anything that would put a big square hole into a collision bulkhead should be.