Between the several dozen other, in-boat jobs I have to accomplish this winter, I also want to have the anchor well modified over the winter.

Some of you probably read that as "well-modified". Well, no. No anchors will be modified in what I have planned. The chain to which the anchors are attached, however, known in this instance as the "rode", will sink to new depths down the anchor well.

|

| Side view with proposed angled plate instead of well floor |

The other reason is that it is the pit that collects the chain, and not some dank, dark locker forward of the V-berth. This means that the most forward part of the deck doesn't require a hawse pipe in it. The hawse pipe, which routes the deployed or retrieved rode from the chain locker inside the boat to the outside, is a clever way to keep kinks from happening and to keep most of the water out. You can even cap them when not in use. But "most" isn't "all" and the ideal on a steel boat is to keep it as dry as possible.

Another ideal is to always have your anchors and related gear "at the ready", not all down below disassembled so as to keep the weight far back. While this is a real concern on boats lightly built, plumb-bowed or generally of a racing contenance, given the buoyancy of our bow, and its massive construction, there is no compelling reason to cut a hole there just to get the chain lower and/or inside the boat. The second chain, sure. But that's another story.

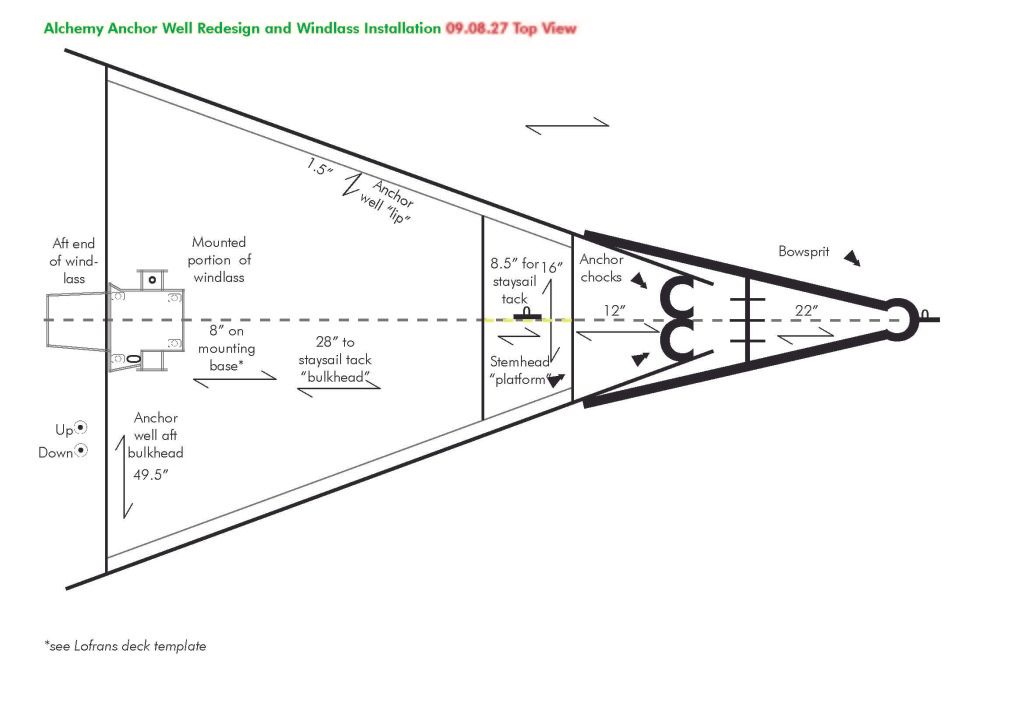

There is, however, quite a bit of logic in getting more volume into that anchor well, primarily to store flaked chain rode in an orderly fashion, and also to ensure that the chain brought aboard by the windlass pictured above doesn't pile up directly under itself.

|

| Top view: Shall I fab up a fibreglass lid? Some think so. |

I hope all this will give me the ability to carry more chain on deck (but lower, which is better for stability and pitching) and will allow me to flake it without kinks, and without putting in an intrinsically leaky hawse pipe.

Lastly, here's a very interesting, informative and alas, unhappily ended tale of anchoring in bad conditions that made me think. It's from www.sailinganarchy.com, so consider yourself warned about the salty language: http://forums.sailinganarchy.com/index.php?showtopic=100772