|

| Winches. If you think they are expensive, wait until you have to get spares for old ones. |

I had reason recently to relate a winch-servicing trick that I thought I had cleverly invented; alas, it's been done by every fourth sailor since the invention of the things. Still, I'll expand on it as it's an area of boat maintenance that is rarely ignored by the racer, but to judge from the appalling screeching one hears on some peoples' boats, is occasionally neglected by cruisers of the recreational ilk. That subject is winches.

Typically, I "service" all of our boats' winches every two seasons. This involves partial or full disassembly of the winch bodies, cleaning, lubrication, replacement of worn parts if needed, tightening of the winch bases, the occasional sealing of the winch base mounts, and reassembly.

Exceptions are made if the winch is showing signs of dirt or binding or if I've just been using them a lot, or if, say, I pick up a pair in need of rehabbing. The requirement for service is dependent on intensity of use, climate, and, realistically, free time. If I raced 20 times in a season with plenty of short tacks and people bigger than myself doing the grinding, winch servicing of the primaries two or three times in a season would not be considered excessive.

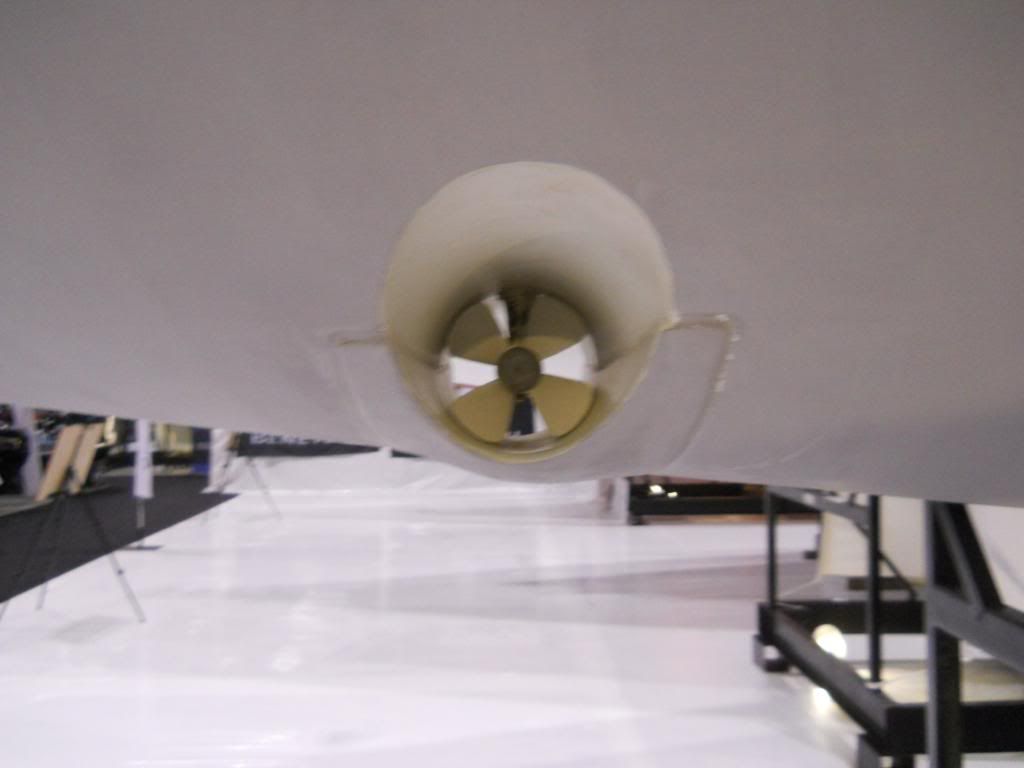

|

| Warning: It's never on a neutral background, nor is it this clean or this tastefully lit. I find a bright headlamp can help on a cloudy day. |

| One wishes as a skipper to avoid casting a pawl over the proceedings. |

Here's the drill for coaming-mounted or deck-mounted primaries, secondaries and halyard winches:

Cut a circle in the box bottom the same diameter as the winch base.

Cut down the height of the box to slightly higher than the height of the winch.

Place the box over the winch and remove the hex bolt(s). When you lift off the winch drum, you are far less likely to scream when the little pawls and pawl springs pop off, because they will fall into the box and not over the toerail and into the sea.

UPDATE 14.01.23: Skilled boat fixer Gary Daggett writes: I have used that [the boxing the winch method] before and I add a little bit to it. I have a couple strong magnets and I use some painters' tape to attach them to the inside of the box so that I can just stick the clips and loose parts to it that will stick. For the pawls and other little pieces that don't stick to the magnet I run some tape sticky side up and just stick the parts to the tape so they don't slide or roll around. I do much of my work on the water so keeping them parts on the boat are really important as you pointed out.

Thanks for the tips, Gary. Interested readers in the greater Chicago area (and this is a rare endorsement from this blog) should consider Gary to help them service, fix, restore or modify their boats.

Service and reassemble as per your winch manufacturer's guidance. Don't be discouraged if your winch is no longer made or is elderly: there are many old winch resources on line in which exploded diagrams and even spares can be found. There's also a fair bit of interchangeability in parts: when I lost overboard a pawl spring for one of Valiente's extinct Barlow 26 primaries several years ago, I found that the equivalent Lewmar pawl spring worked perfectly. But, as this instructive piece from the blog of S/V White Pepper indicates, a well-built winch can come back from a state of neglect and should outlast its owner.

As for my initial, unboxed winch servicing adventures, all I needed was a ridiculous amount of cash for one tiny bit of spring.

And yes, it was exactly this sort of sad and surprisingly expensive event that prompted me to develop this "pro-tip".