The above shots show the progression of the rising waters at our club between May 6 and May 14 this year.

It's a rerun of the destructive flooding of 2017, and while our club, by virtue of having floating and not fixed docks, and the building itself built on a low podium of sorts, is in less trouble than many other lakeside operations,

things remain tense.

|

| The bridge over excess waters. |

While our previous experience has given us as a club some expertise, even a mild breeze from the wrong direction can send waves against the lawns and brickwork, much of which is now sporting algae and waterfowl and even small fish.

|

| Why, yes, this has made getting masts in problematic. |

Trouble is, there's

no evidence that this will stop soon. At its exit to the St. Lawrence River, Lake Ontario's outflow is controlled by a series of dams, but there's a hard limit to how much water can be sent downstream to Montreal, which has had arguably worse flooding this year. So the rest of the Great Lakes in a very wet winter and spring continue to gush, via Niagara Falls, in our general direction.

|

| Trenton shed number 2: Oh, this was annoying. |

Meanwhile, work proceeds on the time-honoured labour principle of "you can sleep when you die". The newer of the two sheds in Trenton was, at some cost to temper and knees, completed by my father-in-law and myself despite some clear issues at the plastic shed plant. Never again. Wood and planks for me, or steel. Yeah, steel's the ticket.

|

| I don't even know what will go into this yet. But something will |

The new tenants are working out fine, despite their discovery of some house-flipper mischief that dogged their enjoyment regarding certain plumbing and electrical half-assery. So bills have been paid.

|

| Main post lazyjackings. |

The mainsail is on, and the lazyjacks (including a bosun's chair rereeving by Mrs.

Alchemy) are lazyjacking. From a distance,

Alchemy's starting to look functional.

|

| Those empty slips are now occupied. |

Beneath decks, improvements continue. The new hydraulic lines are installed (autopilot to come) and "anti-chafe" applied.

|

| There's not the rub. |

In the same vicinity, I chopped the floor in half and added handles to make the "aft bilge" accessible. It's not a huge space, but it's dry and awkward objects, such as the

storm shutters, can nestle there comfortably.

|

| That's the propshaft log down there. |

The anchor's on again. Yes, I need to "borrow" the swim deck of the powerboat ahead of us to safely do this job.

|

| The rustier chain is to the Fortress "lunch hook"; the main anchor chain is partially in the lashed black bucket. |

|

| Add caption |

|

| We hired three labourers at short notice to help us hump this thing into place. Never have I paid cash so happily. |

One of my tenants is a contractor and very kindly drove our ridiculously heavy boat cradle off the club property and to the somewhat damp Trenton backyard "depot".

Meanwhile, back aboard, some long-standing safety matters were in play. We've never had reefing or preventers rigged on

Alchemy, but that's changing. The reefing's pretty straightforward: we're going with

two-line "slab" reefing for simplicity and because it's easy to work at the mast for us. Another advantage is that dacron-covered Spectra/Dyneema line means less weight aloft with no loss of strength. String theory in action.

The padeye above is the terminus of the Spectra-core line that goes on starboard side about the length of the boom and which is secured on a horn cleat near the gooseneck by a loop of shock cord. Running from the cockpit to beefy blocks either side of the bow and then outside of the forward shrouds are two 1/2" Dacron lines, which are stretchier than the Spectra-core. Tying or shackling the boom line to the bow line and cleating off means that downwind work is made safer (and easier on the rig) by

"preventing" crash gybes. We are still considering a

boom brake, but our mainsheet tackle, at 6:1, is already good at controlled trimming, so we'll review later on.

|

| I call it "Frasier". |

The stern was adorned with the remounting (after the SS base finally turned up) of the deck crane, which is used to bring aboard dinghy motors and provisions of unusual size, delivered by tender.

|

| Stairway to heaven. |

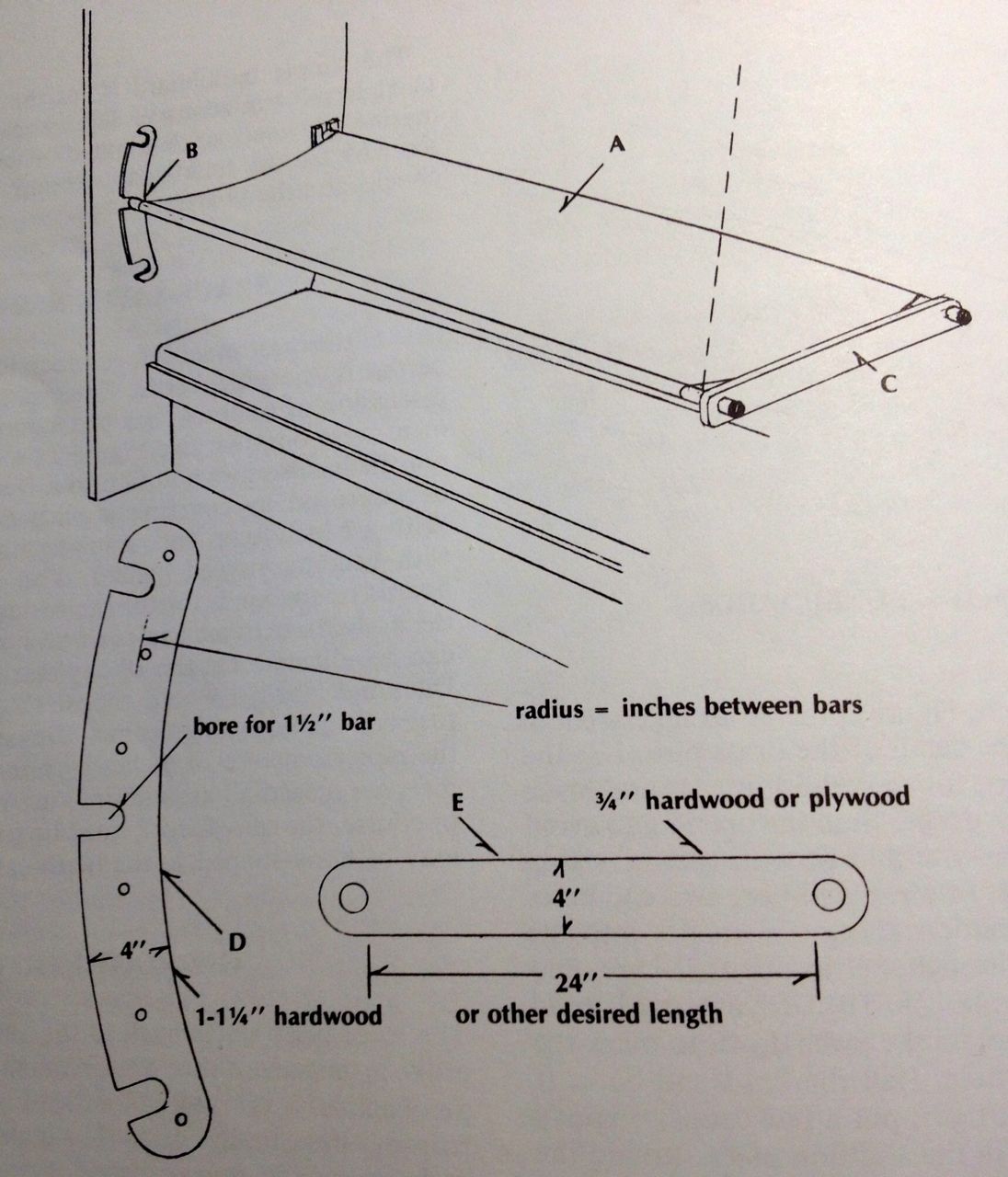

I "fabricated" (using a length of wood, a shop vise and main force) a third tabernacle step for Mrs.

Alchemy to be able to reach the top of the mainsail cover, the mainsail halyard shackle and other areas a little too out of reach for a 160 cm. skipper. Don't let the size fool you: that little tab can take my weight. The angle is on purpose...it just needed a quick filing of the edges.

|

| Lexan, stainless steel: two things tricksy to drill. |

A salvaged sheet of 3/8" Lexan shall serve as storm shutter material for the aft cabin portlights and the pilothouse windows forward. We really don't need them elsewhere.

|

| Shifty, if you ask me. |

A long-time ambition to have an outside throttle-shifter is about to be realized this week as the existing Morse cables to the engine will be paired with two more similar to special Teleflex fittings which allow either the aft deck throttle-shifter or the pilothouse shifter, assuming both are left in neutral, to operate the diesel. This avoids having to purchase

"yokes" for 2 into 1-style cabling, which saves money for us and reduces complexity inside the boat.

|

| I like to keep the engine clean, it's a clean machine. |

Measuring up the preventer geometry, I found the existing mainsheet was too short to allow the boom to get fully "over" in order to be preventered. So I sewed a second line onto the first to see how much more I'd need. Turns out 25 more feet was the answer. Remember, at 6:1, that gives me only four more feet or so extra swing. I took the opportunity to reduce the mainsheet diameter from 1/2 inch, which was binding a bit when wet, to 7/16": the loss in ultimate breaking strength was tiny in such an otherwise robust setup, and while my hands prefer 1/2" (which are the diameters of the halyards and sheets), this is easier to coil down in such a long length.

|

| Full and by. |

We had the Dacron cover of our spare halyard fray off for a number of feet: turns out that some of the necessary clearances of our busy halyard configuration allowed some chafing to occur. I (again) sewed a new line onto the old and rove it fairly easily over the sheave. The former halyard will become spare docklines of unusual strength once the cover is lashed back into place and whipped.

|

| This is less confusing than it looks. |

Lastly, our old Easyblock double block, used for the portside combo leading aft of the port jib sheet and the furling line, was taken off active duty in favour of the HARKEN DOUBLE BLOCK, in all caps because of its expense and terrifyingly competent appearance.

|

| Block apps. |

Meanwhile, it's getting Biblical out there.

|

| Yesterday (May26, 2019) on the access road to the club. |

The storm drains are reversing and lake water is creeping onto the road. We've heard rumours, which Mrs.

Alchemy wisely discounts, but still...that the massive current in the St. Lawrence seaway system may complicate locking down this summer, as is our intention. So we will keep out the customary weather eye. I'm glad I pushed the masting as fast as I could at the beginning of May. Seemed prescient.