I was once ignorant and accepting of the logic of boat design. I'm still ignorant...I can't even draw Bambi...but certain features of even the best of boats can annoy me and strike me as continuing to exist not because of logic or even utility, but because of habit. Examples can include restricted access to critical systems or components, like seacocks or engine parts or tankage. Like when I realized my SS water tanks had decent access ports (good) which were within one centimeter of the underside of the pilothouse floor (stupid).

|

| Measure twice, oh, to hell with it. |

But

nobody's perfect, right? And one person's

bad or compromised design is another's

beloved vessel. Provided the boat in question doesn't sink while it's spantaneously combusting,

de gustibus non est disputandum.

|

| A typical modern design with a typical windlass and chain setup. Photo (c) Tom Irwin |

But, having demonstrated love and tolerance for all boats and those who sail in them, why the hell are anchor lockers at the front of most small yachts? It

has occurred to me of late that few sailors in my experience does the right thing in

terms of the physics of ground tackle. Logically, you would want the

windlass right in front or beside the mast, with no centerline hatches in the way, and

that centerline space covered in either a stainless strip or even an inset

"gutter".

|

| As one does on HMCS Montreal. |

The chain or rope rode would go down a

spurling pipe forward of

the mast (the hawse pipe is where the chain rode is routed off the bow and into the water, by the way) into a bilge or keel locker very close to the

center of gravity of the boat. This locker could be in the aft corner of a cabin or would be built as part of bulkhead

involving the head, so the chain pipe (which would be removable for servicing or inspection) could be stowed inside that, which could actually strengthen

the deck.

If the windlass dies, you've got beefy winches on the

mast or deck right to hand. If you choose not to install a chain washdown on

deck, you could have the chain flake down in the bilges over a

perforated plate, under which is a low-profile bilge pump. So you can

"wash without slosh", and then pump the bilge-based anchor rode locker a

lot drier than something forward. You can examine the chain for

defects or service either inside the cabin, or on the deck in a more

stable and sheltered location than the actual bow. Lastly, the wire runs to the windlass are shorter and unburied: easier to service and shorter, cheaper wire runs.

|

| Why, the way this ship does things would wreck the V-berth! |

Getting

the chain over the keel, like getting the batteries under the saloon settees instead of beside the motor, typically aft in most boats,

makes physical sense. I can only assume that habit and an aversion to bringing

the potentially mucky "machinery" into the condo-like interior of most

modern cruisers (plus their limited bilge stowage of many) means this

idea is a non-starter.

But let's look at the problems implicit in the current design choices: Having a load of chain and anchor and machinery weight at the bow leads to

hobbyhorsing, seas over the bow, difficulty staying upright, harnesses and jacklines for the person handling the gear (which is never a bad idea, actually) and a lot of wear and tear from the movement of the stowed chain...despite this, most sailors will tell you that there isn't

really a better spot. Not on most modern yachts. Now, sharp-eyed readers will note that on the ship pictured above, the chain fall (the sloped ramp beneath the windlass) and chain locker are well back from the stemhead, leaving the foredecks blissfully clear and largely untrodden by the crew unless it's

Titanic Tribute Night. But this is rarely done on sailboats.

In the below example, the anchor locker is reasonably well-lidded and the Lofrans Tigres (I think) windlass is bolted to a sunken platform, which, most of the time, will keep it and its electrical connections out of the weather and the deck free of a tripping...or worse...hazard. There's a plastic (probably HDPE) plate forward to take the wear of the chain and anchor shank, and the fall of the chain is being guided forward by a roller. It's as far back as it can go, and this is about as good an installation as is typically found on production boats in my snack bracket.

|

| Roughly analogous to what happens on Alchemy. Photo (c) Sauniere59 |

Of course, while

there is no excuse for poor design, the fact is not only that fewer boats these days anchor much, but also that

fewer sailors know how to anchor, and on occasion seem to be unaware that

anchoring includes etiquette. I'm no Ancient Mariner on the topic, but I see problematic stuff, like insufficient scope, lack of sturdy enough fair leads, rode left on the roller, rarely a snubber or a bridle, etc. Part of that, to be honest, is where I live: it's mostly fair-weather sailors stopping for lunch. But another part is that the habit of anchoring is being lost, I think, because

the activity of anchoring is being discouraged. After all, anchoring is in some ways part of the watery version of the

commons, and while

the tragedy of shared access cuts both ways, there's more money for a marina in renting the visitor to the fuel dock a slip for the night, particularly when s

ome abuse the resource.

|

| The bigger the boat, the more chance of doing the anchor locker concept correctly by having the chain fall aft, low and with no easily breached lid on deck. This is a S&S 60. Photo (C) 2011 Practical Sailor |

But back to the dilemma of anchoring and ground tackle, which is almost invariably heavy (

even if there are exceptions) and is best kept aft and low, but usually isn't. It's not like the problem is unknown: Practical Sailor had a couple of really good articles

here and

here a few years ago. Many of pros and a greater number of the cons are enumerated. But if the best practice of ground tackle management is to stow chain low and aft, why is this so rarely a feature of modern production boats?

A large part of the reason is that many people who own boats prefer not to be reminded that they are actually on a boat, I think. They want the "working" part of the boat (the backing plates, seacocks, pumps, engine compartment, tankage and yes, anchoring gear) to be invisible in the "living" area, and banishing the often smelly and rusty chain to the pointy end is one way to do this, even if in terms of the physics of sailing the boat it's like putting a fat kid on the very edge of the see-saw seat.

|

| Custom, homebuilt projects can think outside of the anchor locker if they are willing to commit to non-traditional layouts. Diagram (c) https://framsblog.wordpress.com/ |

In the diagram above, which is from the blog of a Dutch trimaran builder, the chain locker is well-aft, giving the height needed for an effective

chain fall. This is the distance and angle that chain runs off the windlass's

gypsy so that it piles neatly in a pyramid at the bottom of the space provided.

|

| I find interesting this blog author's contention that figuring out the angles of his chain fall had to be derived empirically and not from an established set of parameters. Diagram (c) https://maringret.wordpress.com |

Now, getting the chain aft on the premise that this is better needn't involve radical surgery: one boat builder

found even eight inches aft made a difference and also introduced me to the rather useful and economical concept of the

recycled tire garden trug as a durable receptacle for piled chain. This is easier to remove and clean and cheaper in time and dollars than was my idea of making a triangular box with several coats of

Rhino Liner applied.

A related approach is seen on the rather beautiful S/V

Jedi, a Sundeer 64. Here the chain run on deck is taken well back to an offset windlass and protected hawse pipe straight down into a dedicated locker.

|

| The best option to my mind involves a willingness to surrender a bit of internal space, but so what? It's a boat! Photo (c) http://www.sv-jedi.org/ |

Now, I thought I had all this ground tackle nonsense

sussed out years ago.

Alchemy came with a relatively shallow, uncovered anchor "well", which carries some 200 feet of chain splayed about only 14 inches below deck level. The positives were (and remain) that this well is dry and protected by pipe rails. Losing 14 inches in height means the forces in a seaway attempting to throw crew off the boat are mitigated, somewhat. The drain hole for the anchor well is relatively high in the stem; even in a plunging sea, there is enough buoyancy in

Alchemy's bluff bows to keep the anchor well drain hole out of the sea, and the area is shallow enough that even brimming with ocean, it wouldn't drag down the bows before it self-emptied.

|

| Conceptually in 2009, because I got absorbed with repowering and detanking. |

As can be seen, the "well" is basically just a place to get sorted. So I thought "hey, why not make a nice deep bucket? At the front of the boat? I'm sure I could make a lid for it!"

|

| This is actually represents a vast amount of cutting and welding. And would set the mandatory lifevests on fire. |

But while this would work, it turns the bow into a bucket, leaves far less prospective anchor well "floor" in which to stand, and doesn't move the chain back so much as down, while removing the aspect of "self-draining" that is desirable in a steel boat.

|

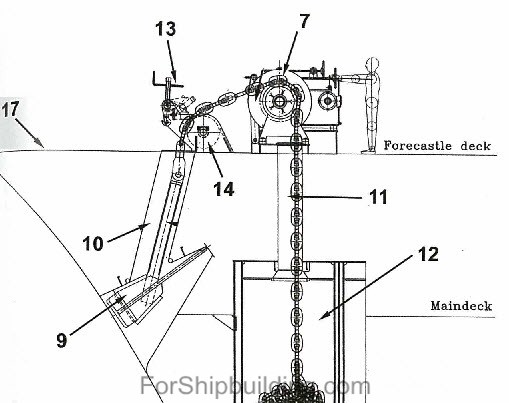

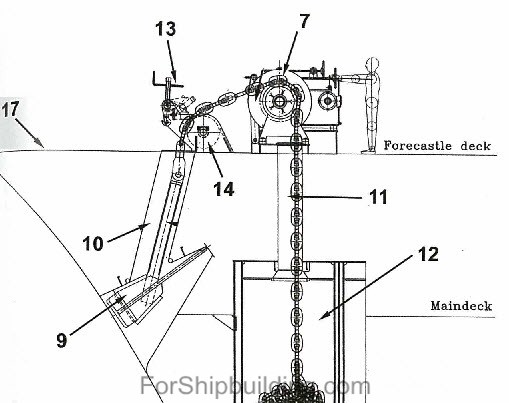

| "Spurling pipe" is number 11 and is the least likely clue in Pictionary. |

So my new thinking is to leave well enough alone (pun intended). The forepeak workshop space is seven feet aft of the stem; I can move the windlass about five and a quarter feet back, almost to the forepeak hatch frame. This will keep the windlass slightly more protected and out of the weather and will leave the well as a place for chain management and cleaning, a rode footbath, so to speak. The chain fall can then be a simple pipe from the underside of the deck, in the same "empirical" combination of straight and angled spurling pipe down to a floor-bolted trug. This means there is no bucket, no welding, no lid, just a lined hole in the deck that pipes chain into a sort of soft bucket. Chain is cleaned on deck before it is stowed low and several feet aft, and I can keep the buttons to work the windlass when in electrical mode better protected, another win.

I think I'll start measuring twice and cutting once. I may have just talked myself out of an expensive mistake.