Between the several dozen other, in-boat jobs I have to accomplish this winter, I also want to have the anchor well modified over the winter.

Some of you probably read that as "well-modified". Well, no. No anchors will be modified in what I have planned. The chain to which the anchors are attached, however, known in this instance as the "rode", will sink to new depths down the anchor well.

|

| Side view with proposed angled plate instead of well floor |

The other reason is that it is the pit that collects the chain, and not some dank, dark locker forward of the V-berth. This means that the most forward part of the deck doesn't require a hawse pipe in it. The hawse pipe, which routes the deployed or retrieved rode from the chain locker inside the boat to the outside, is a clever way to keep kinks from happening and to keep most of the water out. You can even cap them when not in use. But "most" isn't "all" and the ideal on a steel boat is to keep it as dry as possible.

Another ideal is to always have your anchors and related gear "at the ready", not all down below disassembled so as to keep the weight far back. While this is a real concern on boats lightly built, plumb-bowed or generally of a racing contenance, given the buoyancy of our bow, and its massive construction, there is no compelling reason to cut a hole there just to get the chain lower and/or inside the boat. The second chain, sure. But that's another story.

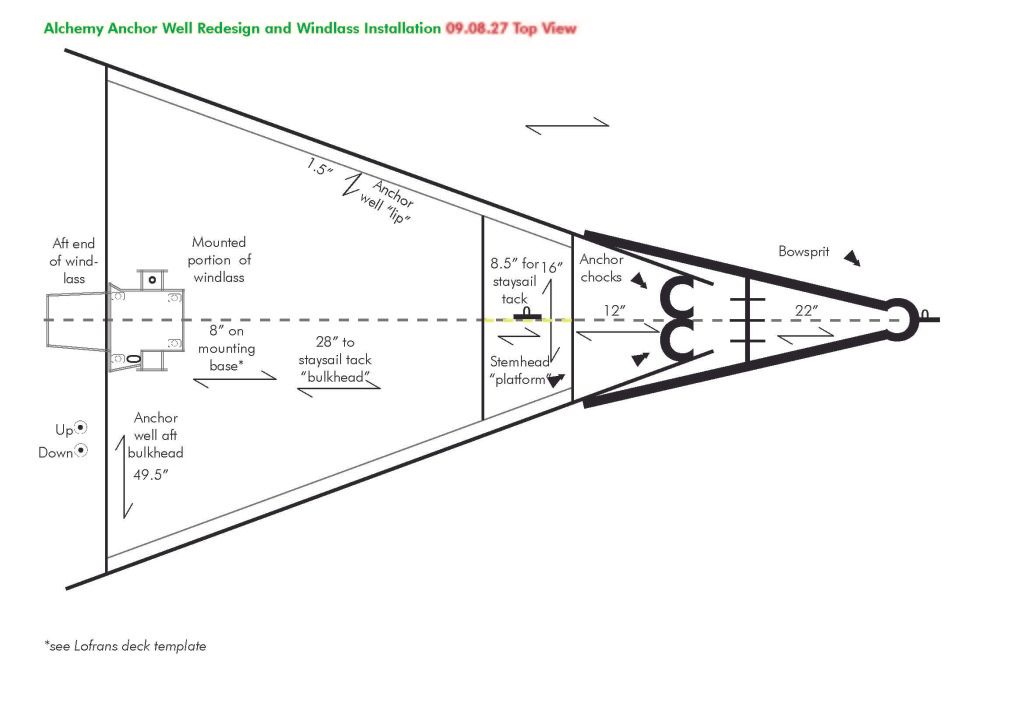

There is, however, quite a bit of logic in getting more volume into that anchor well, primarily to store flaked chain rode in an orderly fashion, and also to ensure that the chain brought aboard by the windlass pictured above doesn't pile up directly under itself.

|

| Top view: Shall I fab up a fibreglass lid? Some think so. |

I hope all this will give me the ability to carry more chain on deck (but lower, which is better for stability and pitching) and will allow me to flake it without kinks, and without putting in an intrinsically leaky hawse pipe.

Lastly, here's a very interesting, informative and alas, unhappily ended tale of anchoring in bad conditions that made me think. It's from www.sailinganarchy.com, so consider yourself warned about the salty language: http://forums.sailinganarchy.com/index.php?showtopic=100772

7 comments:

Is there a way to get into your new chain locker ?

The reason I ask is that I have a 46' Bertram on Lake Erie and have had to go into the chain locker and untangle the chain because in rough weather the chain was lifted and shifted so the chain would not come out.

Yes I understand that the 45 deg. angle will help prevent that, but I think it could still happen.

Bill Kelleher

Perhaps I wasn't entirely clear, but there isn't a chain locker in the sense of a chain stowage area beneath the floor of the anchor well, and inside the boat.

My design is merely modifying the anchor well from a flat, triangular box to a sloping downwards, deeper triangular box. This is so the chain will (I hope) fall away down the slope, away from the chain winch on the windlass.

Therefore, the logic of the slope is not to avoid tangles so much as it is to avoid bunching up and "stacking" of the chain so as to interfere with the gypsy (the chain winch) and the fall of chain from it.

I think the chance of the chain getting tangled in the well is probably as high as if it was being fed to a locker via a hawse pipe, but the difference here is that I can stand on the chain or the "lip" of the well and pull on the chain from above, which gives me space, light, mechanical advantage and gravity advantage in clearing any kinks in the chain. Another vote for keeping the well (if modified and made more voluminous), and against stowing it below.

Like most sailors, and unlike most fictional depictions of sailing, I will likely flake out the chain in long loops on the deck before I drop the anchor in order to figure out how much to deploy (via bright paint marks on the chain to indicate depth), and to make sure it will run freely when dropped.

Thanks for the question, Bill and good luck with what is a pretty big boat for shallow Erie.

Rhys

Thanks for the clarification.

That makes it a lot easier than mine, as I have to stick my body through a 18 inch door and try to straighten mine.

Bill

My concern with rode wells is what is holding all that rode onboard when you fall off a wave or get a knock down? ~300 kg of chain and 100s of feet of line flying around the deck or over the side would make things rather dicey in a seaway. I see you tenatively plan on a fiberglass cover, recommend you make sure it has the strength to hold all that chain/rope in the well.

Hi, Burry...hope you liked your fishing picture! While the chain hasn't shown a tendency to move much on Lake Ontario, I agree that doesn't mean much on the open sea. The fibreglass cover would be sturdy enough to support my weight, so yes, it would be robust. I have also considered aluminum plate, but that involves an extra consideration of dissimilar metals and galvanic isolation...which is not going to be new to me as I want aluminum plating for the engine bay hatch (a clamshell on gas struts), and aluminum, doggable doors on the companionway entrance and the entrances to the saloon and aft cabin.

No matter what I decide to secure the well itself, I would certainly put in a heavy mesh, tied-down netting (like trampoline "netting") to keep the chain in place, even in a knock-down. That means multiple attachments, which can easily go through the 1.5 inch lip surrounding the well.

There is also no particular problem with bringing the entire chain inboard on passage into the forepeak workshop space via the forward hatch (a heavy steel lid). As I would flake the chain on deck prior to anchoring anyway, it doesn't necessarily need to be in that well at all offshore; it can be deployed in the hours before landfall and anchoring.

But you are very correct in pointing out this consideration should influence my design of how securely I stow the chain. Thanks.

Marc, I hope that after you finish with your chain locker and windlass installation that you won't be forced to flake chain out on the foredeck before dropping the hook. Mark your chain beginning with 10, 20 and then 50 ft intervals. Our 250ft primary chain has painted stripes and now those neat coloured plastic inserts (they really stay on.) You will not really know the water depth until you choose the spot. We have never really seen anyone pre-flake chain before. Can't your windlass power in reverse...or at least allow the chain to free fall?

Bruce Clark does this as does anyone I've seen who regularly anchors. Pre-flaking makes sense to me, as does a controlled drop...unles I'm in 15 feet and little tide.

I've seen paint marks, clipped cable ties in various formations and colours. The inserts are new.

My windlass can free-fall, power raise, power fall, and manually hoist up and down. I picked it on the basis not only of sufficient hauling power but also the ability to handle rope and chain, manually or electrically. So yes and yes is the answer.

My new Fortress is assembled in tha garage and is going on Valiente on a chain/rope rode right after I launch in a couple of weeks.

Post a Comment