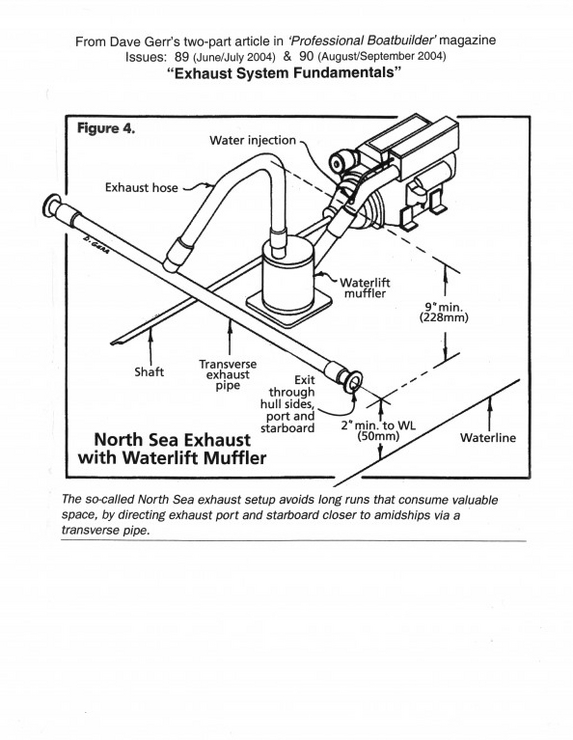

| The number of boats containing all of these elements (fab waterlift, muffler, gooseneck) is likely not great. |

Work and an abominable winter here in Toronto put paid to many scheduled boat upgrades this winter: the few days it was clement enough to shovel the decks (yes, this was required more than once), I was often bogged down with paid labour, a good portion of which goes toward boat gear and other arcana for our ark.

But spring, in a sputtering, half-arsed fashion, has arrived just short of our launch weekend, and some windows of non-freezing, non-hailing weather have opened up. I don't need non-hailing except for painting and deck work, and I have seven days to finish that.

So I decided yesterday to dwell in the still-chilly bilges of Alchemy, and fashion a means by which the diesel's elemental effluvia of smoke and water will leave the boat. In my experience, sad but commonplace, such reasoning is far from elemental. It requires more than a superficial understanding of why water wants to go where it does, and concepts like back pressure and air pressure and anti-siphon loops, oh, my. I've had cooling water, which is the part that makes a wet exhaust wet, back into the engine more than once due to the failure of various components and, I have to admit, an incomplete understanding on my part of the forces at play.

Basically, diesels need to be cooled. They typically have "internal" coolant in the form of glycol-type antifreeze or "Prestone" circulating under pressure through various passages in the block. This is piped through a heat exchanger bolted on the side of the block. Much as air and fans cool a radiator in a car, so the "external" pumped seawater takes engine heat away from the internal coolant circuit and then, in the form of somewhat warmer water, into the flow of exhaust gases and then out of the boat. Confusingly, the two circuits are called "raw water" (sea water from the outside) and "fresh water" (not water at all, but antifreeze, which has higher boiling and, obviously, lower freezing points). Boating's funny that way.

"Wouldn't it be easier just to pump cold lake or sea water through the engine directly?" some might ask. The answer is yes, it would, and this is the state of affairs on my rather basic Atomic 4 gas auxiliary engine on my 33 footer: I open a seacock and lake water goes into an engine driven impeller pump chamber and then through the block (the bit with the pistons and crankshaft in it) and then into the manifold (to cool the gases a bit before reaching a "mixing elbow" where the water combines with the exhaust and is "lifted" out of the boat (more on this later).

This works because fresh water isn't as corrosive as sea water. This also works because I have a filter basket. If a piece of weed or a bit of plastic bag gets into the raw water circuit, I usually find it here:

| It's appalling what I've found in this sort of thing on Valiente, to which I can only attribute to a lot of sex at the water's edge. |

Fair enough, but why have outside water, which is frequently polluted with various organic and inorganic chunks of horribleness, go through the engine at all? I occasionally "flush my block" at season's end, and I always find sand and fine bits of plastic and whatnot even my precautionary basket filter missed. In theory, the added complication of a separate raw and fresh water cooling setup means the narrow passages of the diesel's cooling circuit never see anything but (presumably non-cruddy) antifreeze, which one changes after a known cycle of runtime. The heat exchanger is a different story, of course; it may see all sorts of crud going through it, lessening flow and therefore the ability to carry away heat, and it may be subject to various forms of corrosion and general damage, particular if one is a little slack in servicing it or paying attention to its appetite for zincs. This is why a spare exchanger is right up there with a spare starter in the "big ticket" list of diesel components the cruiser may wish to consider.

|

| Your overheat warning system can range from "beeeeep" to Star Trek. Photo (c) Setsail.com |

Of course, steps can be taken to lessen the crudification of this important component, and I went over that in a previous post, but while you can use technologies to alert you to problems in the cooling circuit, I think the best course is to regularly schedule a clean-out of the heat exchanger, particularly if you are cruising in waters full of sediment (river deltas and many harbours would count) that will inevitably end up inside your hoses.

This brings us to the exhaust system, which is primarily concerned with the byproducts of diesel combustion in the form of very hot gases, and getting them safely out of the boat. While a steel sailboat can, in theory, have a diesel dry exhaust with the aid of keel cooling, the boat wasn't set up that way and there's some advantages in my mind to keep all the plumbing in one area. Not to mention that wet exhausts are less sooty and quieter than are dry, which, however, are fine on workboats and so on.

If anyone reading this can tell me the difference between a waterlift and a waterlock (both of which frequently have the word "muffler" after them), please let me know. They are at the heart of the exhaust system in that they both "lift" water from below the waterline up and out of the boat, and "lock" it from backing up into the diesel engine, which would explain somewhat the variable terminology.

|

| Both fancy and schmancy, and yet of all the things you can make a waterlock from, plastic is my least favourite. |

I considered getting a fancy schmancy Vetus NLP 50S one for the simple reason that, unlike most boats, Alchemy's exhaust goes to one side (starboard) and therefore something that can rotate 90 degrees off a straight run had its charms. I also liked Vetus gear and indeed have an elderly but effective Vetus waterlock on Valiente. Installing that was the day I found out that my wife can squeeze into the stern of a narrow IOR boat, sufficiently lubricated by swearing, of course.

|

| Basic but functional, and it didn't back up water into my Atomic 4 like thefailed Onan waterlift of unlamented memory. |

But the otherwise desirable Vetus NLP50S was European, and therefore predictably expensive, and it did not answer a related exhaust issue: the need for an anti-siphon valve and hose setup. A more elaborate form of vented loop, these devices contain a small piston-type plunger and spring that allows flow in one direction and not the other. If, as is often the case, the engine is at or just below the waterline, the water from the "raw water side" of the cooling circuit would, without this device, fill up the entire run, and would likely cause water to back up into the engine manifold. Which can ruin one's day and has ruined mine.

|

| That sinking feeling is when the head backs up and sinks you. |

So, understanding where the waterline is on the inside of the boat, where the engine is in relation to that waterline and planning for the vented loop setup is pretty critical. Did I mention that they are important in the plumbing of the heads? Well, they are, and that's a topic for another day.

|

| The KISS option: Take out the valve thingie and run a length of hose out onto the deck. |

Now, it's true that you can just have the "vent" part of the vented loop free of pistons, springs and flappy bits by simply running a length of hose up and out of the boat, to either a skin fitting in the side of the boat (well above the waterline, of course, and perhaps with a gooseneck loop of its own) or even out onto the deck. If you are underway, you'll see the occasional spurt of water when powering through the briny, and which, not being a jet of hot steam, will reassure the watchstander that all, in at least this respect, is well.

But what if you could dispense with the anti-siphon loop altogether?

|

| Now you're talking. This suits me to a T-fitting. |

It's from Dave Gerr's excellent Boat Mechanical Systems Handbook, which, along with Nigel Calder's Marine Diesel Engines, and Charlie Wing's Boatowner's Illustrated Electrical Handbook, are my go-to reference books for trying to make Alchemy mobile, functional and not prone to exploding. I believe all three should be greasily indispensible aboard any self-maintained pleasure craft.

Because my boat so closely resembles in plan a grubby Norwegian herring boat, and because I wanted to know if the missing vented loop and its evil, failure-prone and crud-attracting spring and plunger was artistic error or not, I contacted Mr. Gerr with the following questions:

Hello, Mr. Gerr:

I'm restoring a custom 1988 steel pilothouse cutter sailboat for long-term passagemaking and already have the engine in and lined up. It's a Beta 60 replacing a Westerbeke W-52.

The exhaust outlet for this engine is 2 inches/51 mm. The waterlift muffler I have selected is a 10 litre Centek of the same fitting size which will go partially in my keel bilge.

My old exhaust port is close to the waterline on the starboard side. What I wish to do is to replicate the North Sea exhaust,as I have an identical welded pipe on the port side currently used for bilge water hose. My idea is to run the exhaust to a mixing elbow and down into the Centek, and then up to a T-fitting right under the pilothouse deck. Exhaust plus water would then exit slightly downward (about six inches down the hull over a six-foot run, assuming the T-fitting is more or less centered under the deck) to either starboard or port, both of which would have seacock shut offs for extended sailing periods OR a single shut off just underneath the T-fitting.

My questions, should you be kind enough to give your opinions, are this:

1) Is it necessary to have an anti-siphon break in an exhaust set up where one end of the transverse exhaust (the "high" side) is always exposed to the air? Yes, I have had stuck anti-siphon break pistons lead to kerosene flushes...if I did need this, I would simple run a 1/4" hose out onto the deck).

2) What is the best material to make a T-fitting out of? Stainless welded, galvanized pipe or black iron? I intend to use typical Trident exhaust hose for the supported runs port and starboard.

3) Do I need to take any particular measurements beyond what Beta and Centek recommend regarding minimum heights and clearances? It strikes me that this answer is no, as the system is "open" in a way that (save for the anti-siphon) a exhaust hose to the transom is not.

4) If I wished to put an exhaust alarm or even a solenoid shut-off in line in a North Sea style exhaust, where would be a good spot for that to go? I dislike the idea of a solenoid shut off for the same reason I don't like electric heads: water and amps don't play well, but I haven't decided wholly against it.

In common with other "names" (including Bob Perry, Bill Wallstrom, Ted Brewer, and George Cuthbertson) in the boating world with whom I've had conversation or correspondence, Mr. Gerr was generous with my idiot pestering. His reply:

Glad to hear you’ve found my book useful, thanks. In answer to your questions.No, you don’t need a siphon break on a North Sea exhaust with the outlets above the WL.I recommend against metal in the wet exhaust run. Fiberglass tube and exhaust hose is better in the wet portion—lighter, less expensive, and easier to work with.The governing heights are those from figures 7-12 and 7-13 as well as 7-14.An exhaust temperature alarm would go in the wet exhaust just before entry to the waterlift canister. If it won’t fit there, then just after the canister.Good luck with the project.

Works for me. About the only thing I hadn't considered was having a fibreglass T-fitting to send water to either port, starboard or (conceivably, if we are motoring at zero degree angle of heel) both. Of course, the waterlift I eventually chose is itself fibreglass, which melts/burns at a hotter point than the Vetus plastic, and yet does not corrode like the stainless "pot" waterlift I removed when I hauled out the old Westerbeke.

|

| Did I mention it was $200 less than the Vetus? That's a lot of rum. |

I mentioned the idea of installing large seacocks between the hull and the exhaust hoses, the idea being that if a particularly hard heel defeated the T-fitting riser at that point, the seacocks would keep seawater out of the system and, eventually, the manifold. Only someone bitten more than once by water backing up would even think of this. Naturally, I thought "I will rig a solenoid and actuator so that I can't key the start without opening that valve!" Of course, a length of threaded rod with the keys left hanging on it might work, too. So I would have to consider heat-tolerant seacocks, perhaps some welding, a fibreglass T-fitting at the "top" of the exhaust setup, and some sort of exhaust water temperature alarm, where Mr. Gerr suggested. And lots of the best sort of 44 mm AWAB hose clamps. Below the waterline doings involving hot gases and water is not the place to cheap out with the hardware.

The problem is the date and my time. It's long since past time that I actually get the boat moving, and despite the protractedness of the process, over which my sailor friends continually needle me, I am just as eager to see some signs that my work and cash have achieved something. So I'm going for a kludge. It starts with getting properly hosed.

|

| Common as muck, but apparently now not to code. |

This is a mildly reinforced hose commonly called "red heater hose" or "radiator hose". It also comes in black, but many sailors call it "red heater hose" probably because they are drunk or senile. You'll find it on almost every boat afloat where the wire-reinforced, super-stiff, fire-, chemical and urine-resistant "exhaust hose" is not required. I've got 40 feet of the stuff in the popular 1/2 inch and 5/8 inch sizes spread over two boats and a garage. According to the omniscient Mitch of Genco Marine, the chandlery most convenient to my club, it's no longer approved, to code, or in favour. Checking some sources, including the thoughts of the above-cited guru Nigel Calder, I found that this has been the case for an alarmingly long number of years.

In trying to get away from the loop, I learned I was out of it.

So now one must use reinforced, less-burny hoses at four to five times the cost per unit of royal appendage. The top hose is for the dreaded anti-siphon, and the bottom is some rather nice corrugated exhaust hose to get from the engine outlet to the waterlock. Both are bendy enough to veer the way I require.

The dreaded anti-siphon loop is temporary: I just want to do a "test-fire" to adjust all my controls and to get my engine actually, you know, turning the five grand worth of Super Prop I have pinned to the shaft. The loop is trimmed with a hacksaw to the "25 mm" point, which fits the 1-inch successor to the old red heater hose.

First, I positioned and hooked up the exhaust hose. This involved trimming to size with hacksaw and heavy-duty Dremeling, which obligingly demonstrated that this type of hose would, in fact, burn or at least would copiously smoke. But I got the clean cuts I wanted. The minimum height different is supposed to be 250 mm or 10 inches. This is 9.5 inches. I promise not to motor on a heel before I change it to its final form.

I'm not entirely happy with the location, or rather the lack of "drop", of the waterlift. It's close enought to the centerline of the boat for me not to worry about motoring while heeled much, but it could be a few inches lower for an ideal installation. The only way to do that, however, would be to install sone sort of stand or shelf in the keel bilge, and to back off the shaft to drop the waterlift down there, which would make access problematic. I will have to ponder this one and keep an eye on just how well it's working in real conditions.

The anti-siphon loop hose is stiff enough to stand vertically on its own. For safety's sake, I will use metal strapping screwed to the loop and to the wooden surface aft to keep it from moving around. There is also a small vent line I will install off the plunger bit for further bulletproofing, but, as has been mentioned, this is just a first crack until I can rig up the transverse exhaust and go "loopless".

In trying to get away from the loop, I learned I was out of it.

|

| Pardon the filth: there's more reconstruction underway here than in the post-bellum South. |

|

| I have a Vetus anti-siphon; this is a Chinese knock-off, but I expect it won't be in use very long. |

The dreaded anti-siphon loop is temporary: I just want to do a "test-fire" to adjust all my controls and to get my engine actually, you know, turning the five grand worth of Super Prop I have pinned to the shaft. The loop is trimmed with a hacksaw to the "25 mm" point, which fits the 1-inch successor to the old red heater hose.

|

| It's an emotional time for me, hence the blurriness. |

|

| I did the usual double-clamping with opposing nuts, which sounds like a float in the Pride Parade. |

|

| I didn't forget to clamp that right-hand hose. |

|

| Looks reasonably non-explosive. |

So there's that done. I have to hook up the controls, the raw water supply, the battery cabling and the remote oil filter, plus a temporary fuel supply until I can drain and clean the keel tanks. Given that we launch in a week, I'll likely need a tow to my dock, but such is life. Getting angry about things I can't change will kill me with stress, rendering the entire endeavour pointless. But this to me is some welcome progress. Part 2 will appear (I hope) shortly, and those interested will see that rare bird...a double diesel exhaust in a sailboat. Thanks to Dave Gerr for his helpful advice, and for seeing fit to put such an intriguing idea...to a man sick of kerosene flushes...in his how-to book in the first place.

5 comments:

Hi Rhys, I'm in the process of converting our boat to a north sea exhaust and came across your blog. I was especially pleased to see that I could lose the anti syphon loop. I've been dwelling on that thought a day and am confused. In our setup at least the engine exhaust manifold and water injection elbow are all below the waterline, as is the water lock. So; the engine is switched off, the raw water impeller is old, maybe lost a fragment of blade, the sea water syphons through the system and fills the water lock, rises up the exhaust hose until it reaches the exhaust manifold and floods the engine. Unless there is an anti syphon loop. Am I wrong? Have I missed something? I hope so cos I'd love to lose that loop too. I know the seacock ought to be off but we all know it won't be.

Thanks for your thoughts

Rich

Sorry this took a few days, but it's been miserable winter here! In short, no, you aren't wrong. I can't see how you can get away without a siphon break at the required height above the manifold below the waterline. However, I have some thoughts: The anti-siphon loop you see on my boat is cautionary because I have yet to rig the transverse exhaust. But I have to point out that my manifold is very close to, if not at, the waterline, so I shouldn't have this problem of no siphon break if the volume of the waterlock plus the volume of the hoses is not going to exceed the volume needed to back all the way up to your exhaust manifold, and unless you have a rather deep place in which to put the water lock, you may have to live with the anti-siphon loop. Another issue is that of over-cranking: you can flood the engine with rough starts because you lack the exhaust pressure to empty the "stock pot"; it fills and then there's nowhere for the new gushes of raw water to go. If you have a balky diesel start and a diesel under the WL, it's no sin to keep the raw water off until you've established a proper start: another reason to pay an extra ten bucks for "run-dry" impellers. Get started and then open the raw water. Of course, before you shut down, you can just as equally shut off the raw water and run for 15 seconds, which, depending on the RPM and the total volume of your waterlock and hoses (I have short runs side to side and so have less volume to consider), you can evacuate much of the water and sleep better. Just as easily, you could rig a solenoid, a check valve and a barb to the drain hole of your waterlock, and drain the system into the bilge and let the pumps deal with it. Again, too much complexity for me, but these ideas should work.

But I digress, and I'm going to digress some more: Firstly, a proper way to do things is to change out impellers on an engine hours basis...don't risk them getting worn and losing vanes in the first place. Another caution, which I use on my other boat which has an Atomic 4, is to install a basket style filter between the raw water pump and the block/heat exchanger. If you have bits of vane, this will catch them, along with whatever muck, sand or vegetation that the main Groco/Perko strainer missed. It's a $50 fix that gives immediate warning of damaged impellers.

Now, in the North Sea setup, as I understand it, the best way to go is to have a straight run to an elbow that's at a high point; this goes DOWN to a T that goes DOWN either side to port and starboard. That's tricky and I had to work with a digital bevel to figure out that I had sufficient height between the top of my manifold and the underside of my pilothouse deck. I'm counting on the "air" or "high" side of the double exhaust to allow, when switching off, the water past that elbow to drain out of the boat. The rest will fall back into the boat. Either seacocks (for extended sailing) and/or exhause flaps should keep water from getting back up the spout, so to speak, but I can't discount a siphon break entirely as the fully laden boat, or the boat sailed in rough beam seas or heavily heeled, might see water ingress. So I, too, with a more favourable geometry, might not rule out a siphon break, either.

Part 2 of my reply below...

Part 2...

The importance of letting gravity rather than pumps or exhaust get the water out of the boat is emphasized here (with diagrams and pics): http://www.sbmar.com/articles/designing_a_marine_exhaust_system/

I do have a final thought, however: I have been victim of stuck or otherwise defective siphon plungers, the failure of which dropped water back down into the engine, and I feel a better solution is to simply have a vented loop with the vent line going (if possible) right out onto the deck, with special attention paid to where the actual break is vis-a-vis "downhill". With just a hose, there is no little piston to get cruddy with salt crystals, no problem. You remove the tube and flush it and then clamp it back on.

Some other takes on siphon breaks are found here: http://www.marinemechanic.com/site/page66.html

I hope this has helped. If you have any doubts, first consider the "uphill/downwill" factor, plus what would be the case in a pitching sea. If still unsure, consult a marine mechanic who grasps gravity. Too many boats seem to come up short in this department, and they need not if the subject is understood a little more clearly.

I have a stainless steel waterlock which looks like just a vertical cylinder about 10 inches tall and 10 inches high. After two efforts to cure its leak by getting it rewelded, it is no better, it leaks slightly at the lower weld. The off-the-shelf versions are either too small ie smaller than the one I have (I am not sure how you are supposed to work out how much water they should hold)or too big to fit into the engine room. Check Here

Yes, the SS ones are not only imperfectly durable (I had an Onan one die in freshwater), they are often very hard to remove. You can get them in different dimensionals, and the size is based on the horsepower of the engine, which dictates necessary cooling throughput as per the raw water pump. I'm assuming you have a power boat? I know little about how those are set up in terms of waterlocks, actualy, but Vetus makes an excellent range. I went with Centek because it was simple and it fit and would be easy for me to fix if necessary. It's about the size of a soup pot.

Post a Comment