Behold the mysterious ghost tank.

|

| There was concern this was a refuge for brown trout. |

In my steel

pilothouse cutter refit, I can still find little surprises. Most, with

the coming of wisdom, or at least a lower level of incompetence, are

solvable, but some problems suggest a number of solutions. Those of the

the ghost tank are several, but probably only one is the best.

|

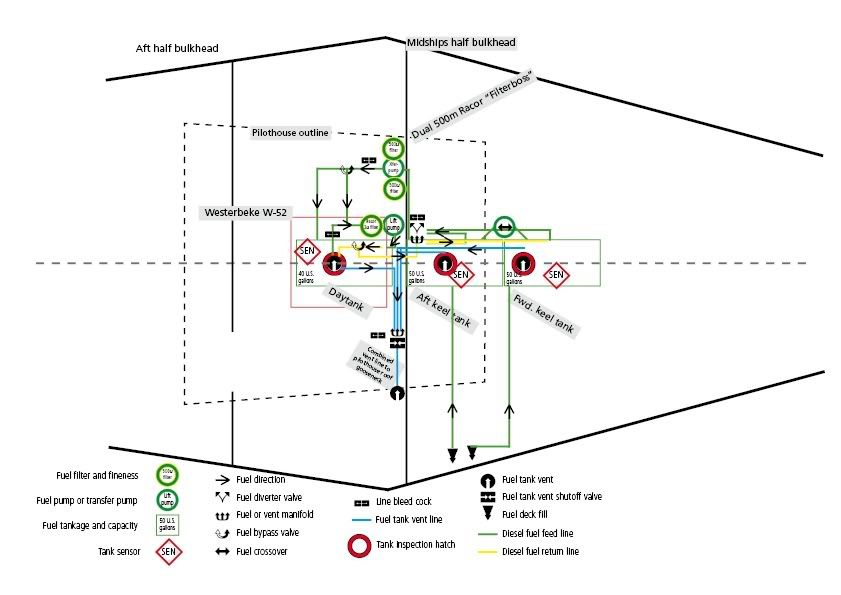

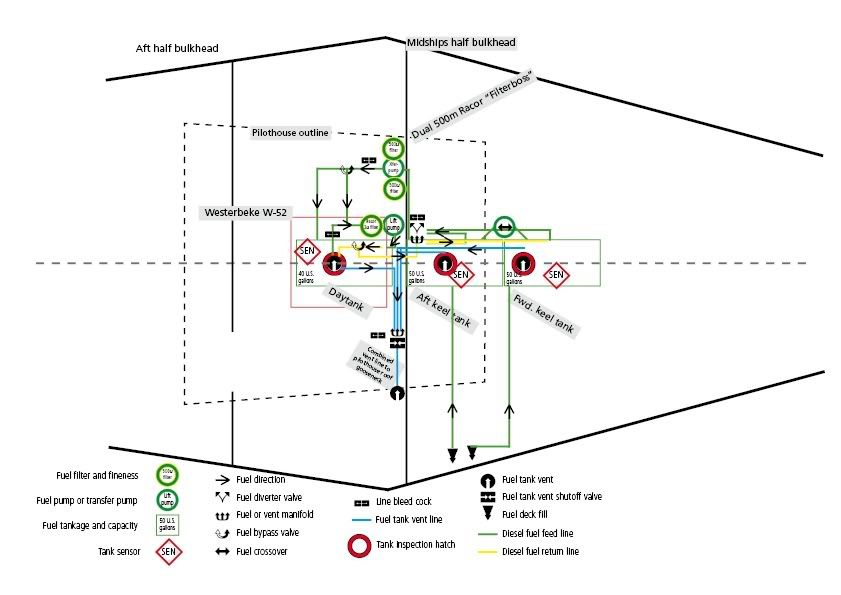

| Astoundingly, although I've clearly been badly delayed in the execution, this diagram is still largely what I want to do. |

As I outlined

a scant three-and-a-half years back (ain't refitting

fun?), I have an unused, approximately 40

U.S. gallon capacity keel tank directly under the engine. Formerly the

original

holding tank, I had no idea until last week (because unbolting the access plate

requires that I fly the engine completely out of the engine bay) if it had been

"put away cleanly", only that the people I bought the boat from (the second owners) had a

new, HDPE tank next to the head.

I have been considering

repurposing this tank as a post-Racor daytank, which would give me a

sort of insurance against contamination from bad fuel going into the

main tanks, and would extend our motoring range to 140 U.S gallons, or

40% more than now.

|

| We found not the usual gasket, but a sort of rubber sheet seal. It came away cleanly. |

Upon finally taking off the inspection plate, I

found a few gallons of water...no smell, thank goodness, of either

chemicals or of its former usage. I also found significant rust:

|

| The pipe here is the "pump out". The plumbing needed to use this as a day tank would be smaller and forward for access. |

At the time we were taking pictures, I didn't think to throw a magnet down to my wife, who was taking the

shots, to determine if the tank was mild or stainless steel (SS). SS would be logical and

would match the water

tanks

I've already pulled out in favour of smaller, easier to service and anchor down

HDPE water tanks. SS would also

(perhaps) suggest that the rust is superficial and could be power washed

off, or treated with something like

Ospho,

over which could go a suitable primer and topcoat that won't foul or

break away into polished diesel.. Frankly, I am not sure if that's the

best course.

|

| Going the "insert" route wouldn't mean I couldn't find a pretty close fit. |

The other

diesel keel tanks forward in the keel are black iron and are full of

diesel, basically as a rust retardant until they are needed for use. That fuel, if even still usable, will need a dockside polish.

|

| I suppose it's uniformly grotty. |

I consider my options as follows:

- If the tank is indeed SS, I would consider sand blasting the interior and applying a coating (if even needed). To judge by inspection

of the lid and the tank top, it is pretty heavy gauge metal. There is

no sign in the bilges or, thank Neptune, on the outside of the hull that

there's any holes in the metal.

- I would consider cutting off the top of the tank, cleaning and coating the interior with something like truck bed liner, and dropping in a HDPE diesel fuel tank with fittings forward (where there is access at the front of the new engine),

- The same as 2, only with a 35-40 gallon fuel bladder. The advantage of this would be the ability to pump out the bladder of fuel and then pull it from under the engine for cleaning or service. It would be secured with bolted-down battens. A clear disadvantage could be the danger from having a working engine directly above this fuel.

-

Fill the rusty tank full of ballast to stiffen the boat and buy a load of yellow jerry cans to tie down on deck.

The

last suggestion is only partly facetious. The original water tanks were

on frames off the hull, and their (full) weight at the sides, plus the lack of

weight in that space below the engine, made the boat almost tender,

which is a ridiculous situation in a steel beast of this nature. The

easiest solution would be to fill the void with shot and cement and let

it harden in place. It wouldn't give me 40% more range, however.

Any constructive suggestions, horrible warnings or sage advice would be most welcome.

|

| Rust never sleeps, but sometimes swims |

3 comments:

Here are my thoughts:

If it is a stainless tank, why is there so much rust? It can't *all* be due to oxygen starvation... can it? If it *is* stainless, then the cleaning option would seem to be the best one. You might want to check around your area - there might be a service like this one here in Seattle.

If you are going to install a plastic tank inside the steel one, why bother coating the inside of it (other than aesthetics)?

I am leery of bladder tanks. They move all the time, and chafe is not your friend.

bob

s/v Eolian

Seattle

Bob, there have been some developments. The tank is mild steel, and is integral. This explains the rust. We've further drained it, but there is still a bit of ice(!) in the bottom.

I am therefore focused on remediation: I want to get that rust sequestered with a rust converter product, and then prime and topcoat the entirety of the tank.

Then I wish to bolt it down again until I haul again in October. This will give me the chance to get the half tonne of batteries in and then I can judge how my trim is affected. There are a number of lead pigs in the forepeak that can be moved aft or out entirely before I decide whether to go with a tank insert or to ballast that area...which the original plans actually specificed.

Anyway, that's today's thought. Thanks for the warning on fuel bladders. I was just chucking that one around.

If you want to put a coat of rust inhibitor on it, POR 15 is an excellent product.

Post a Comment